Aluminium Guttering Systems | Direct From UK Manufacturer

Explore high-quality aluminium gutters designed for long-lasting performance in UK weather conditions. Manufactured in-house using marine-grade materials, our systems offer exceptional durability with a functional lifespan exceeding 50 years and colour retention for over 25 years. Ideal for residential, commercial, and industrial applications, Alugutter aluminium guttering requires minimal upkeep while providing reliable water management at competitive factory prices.

Aluminium Guttering Profiles

Explore the Range

Select a profile to view specific sizes and fittings:

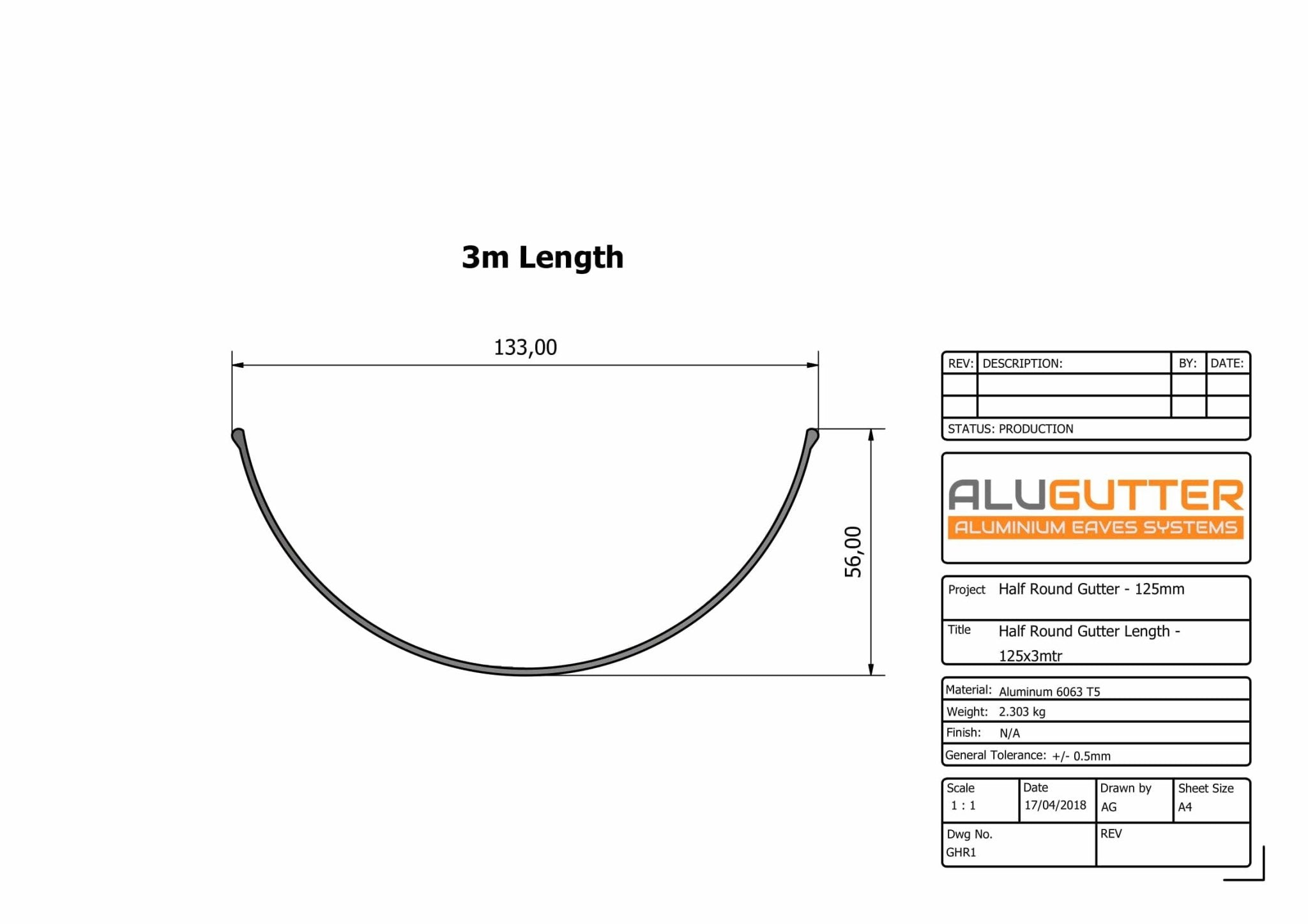

Half Round Gutters – Classic style with efficient flow.

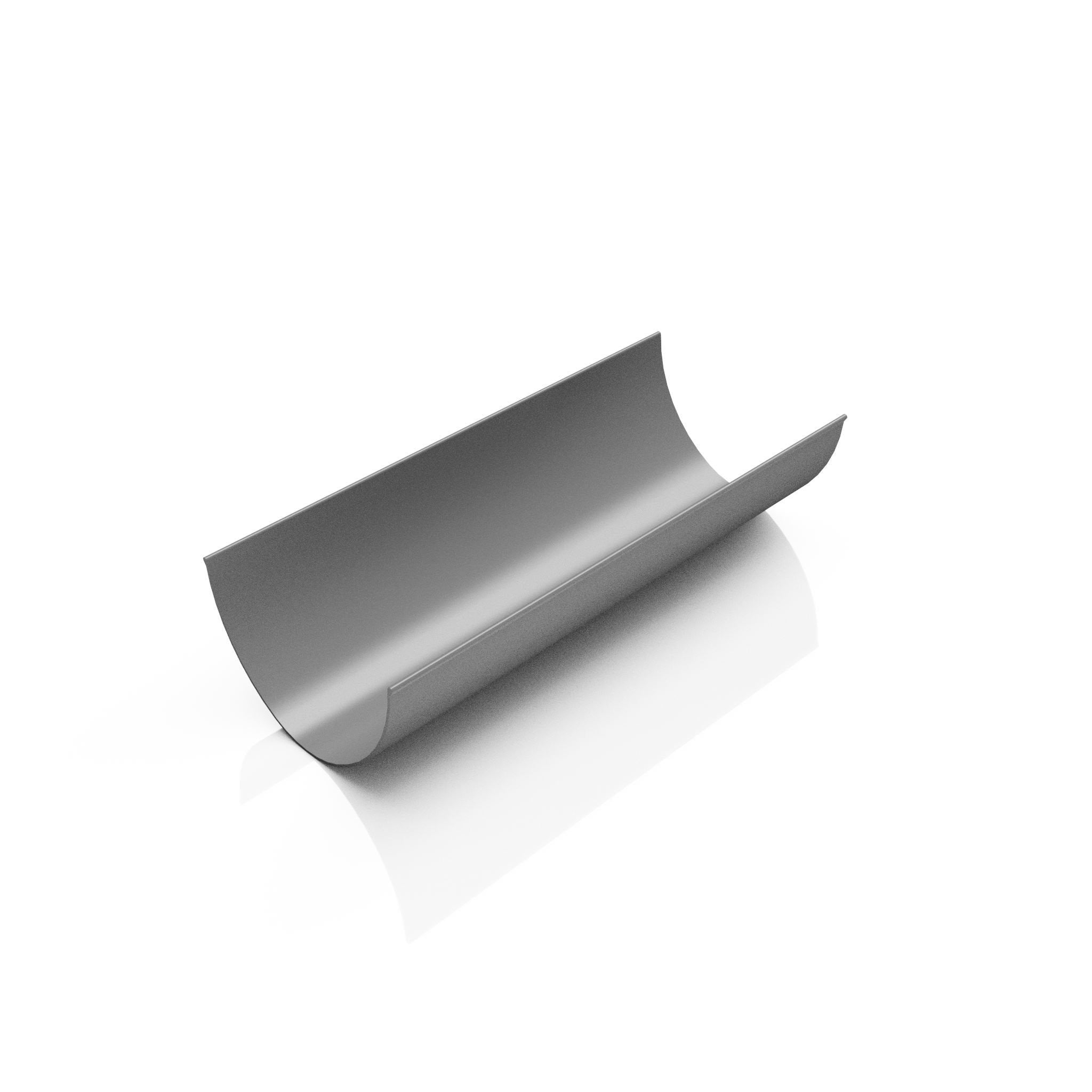

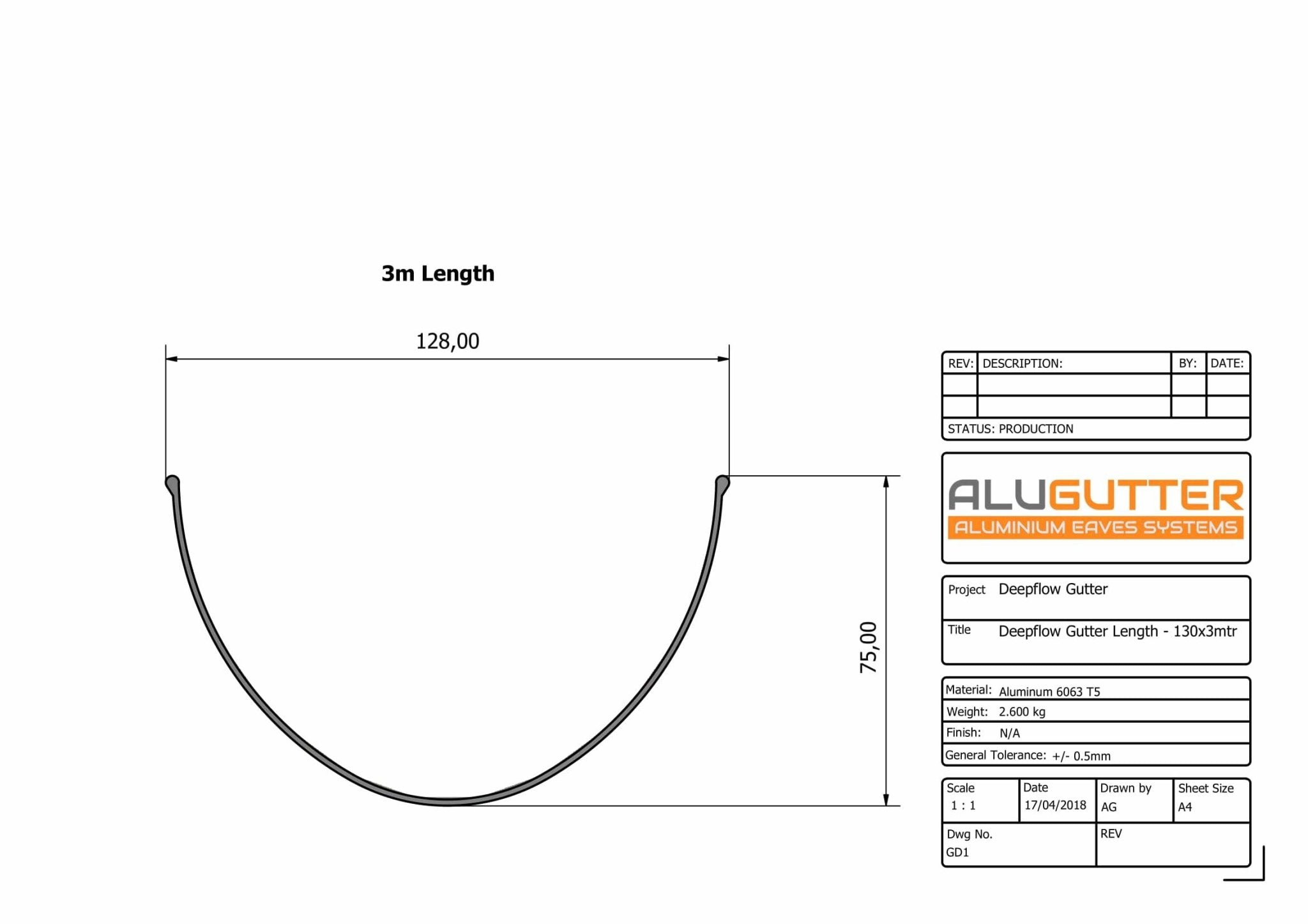

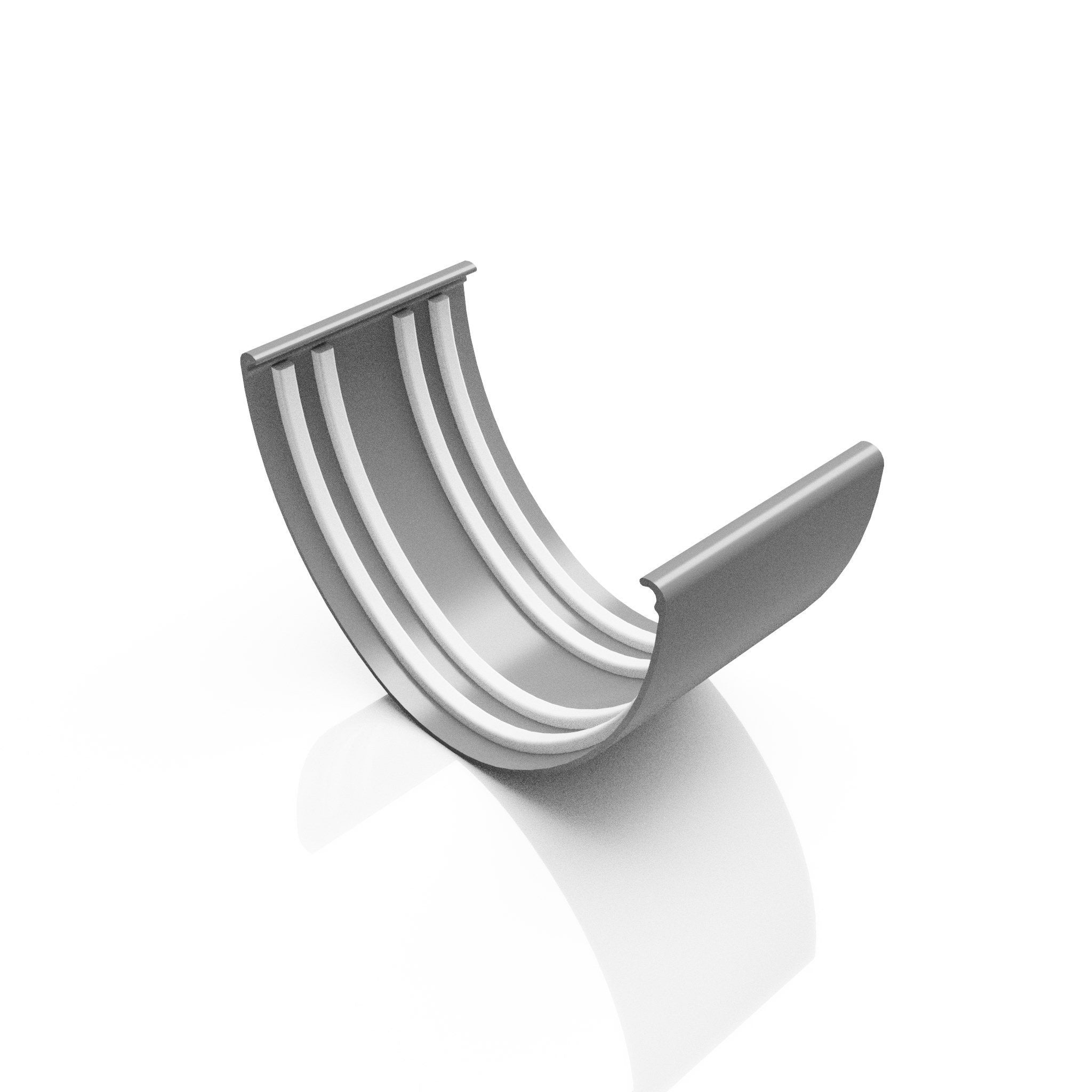

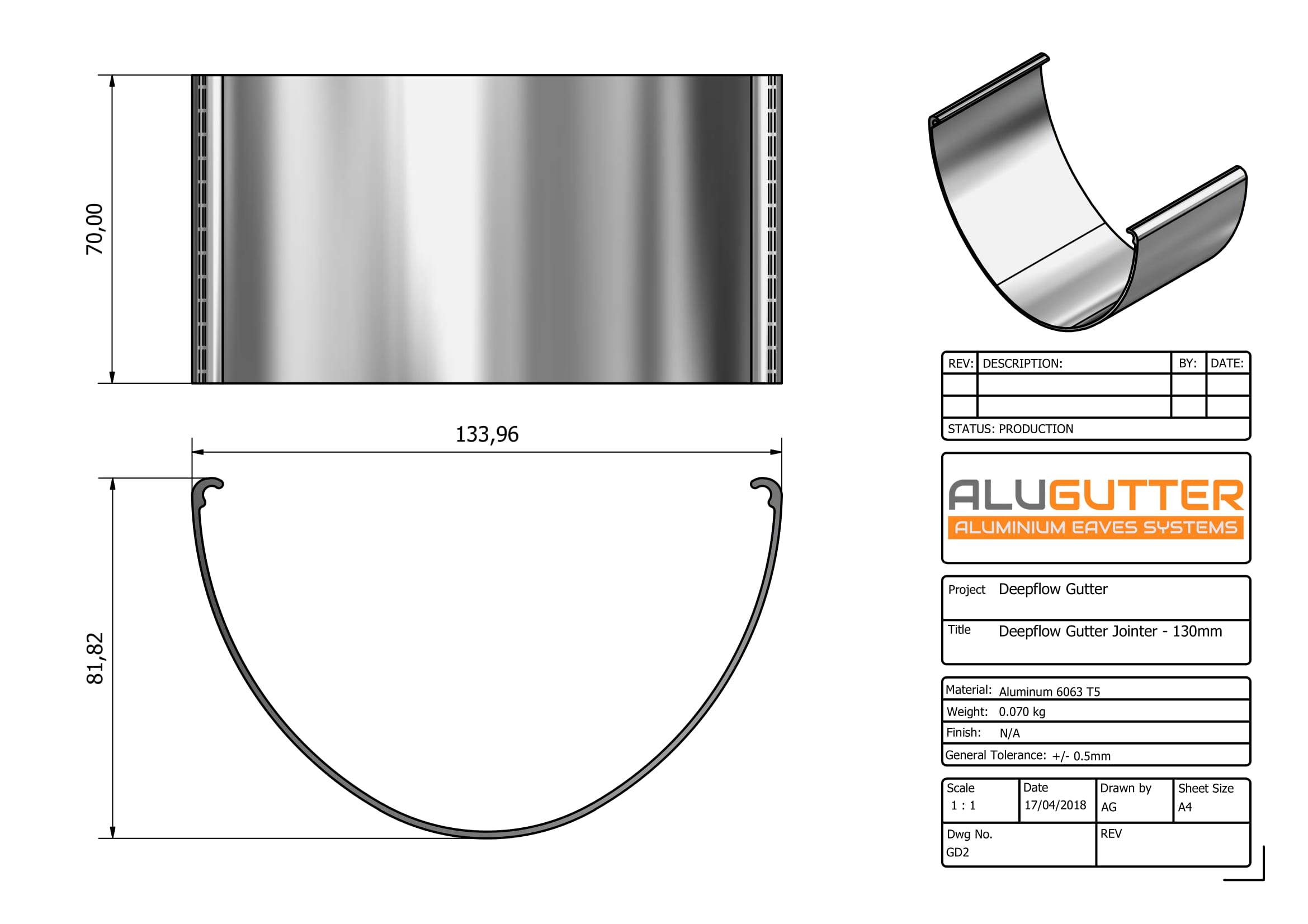

Deepflow Gutters – Enhanced capacity for larger roof areas.

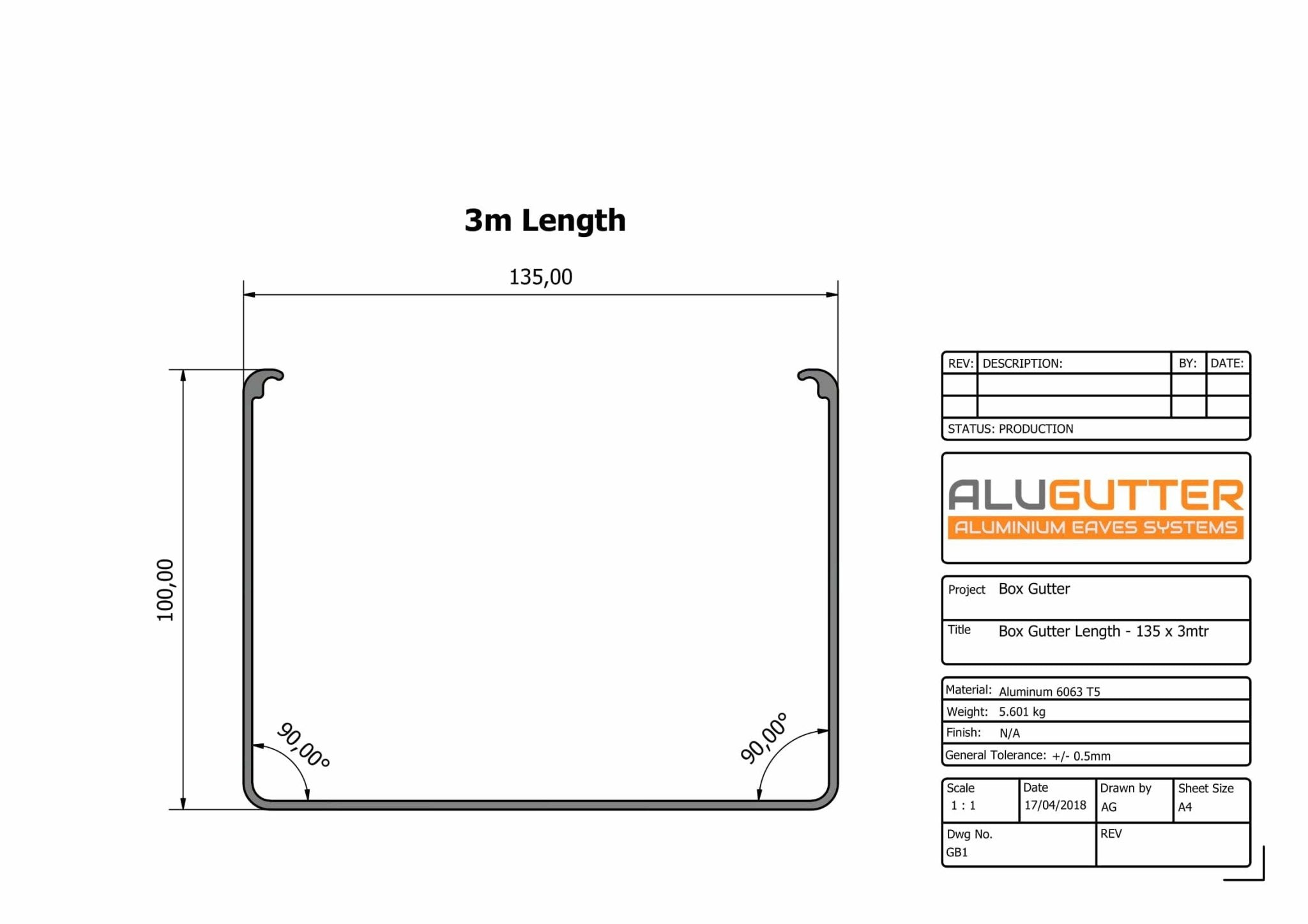

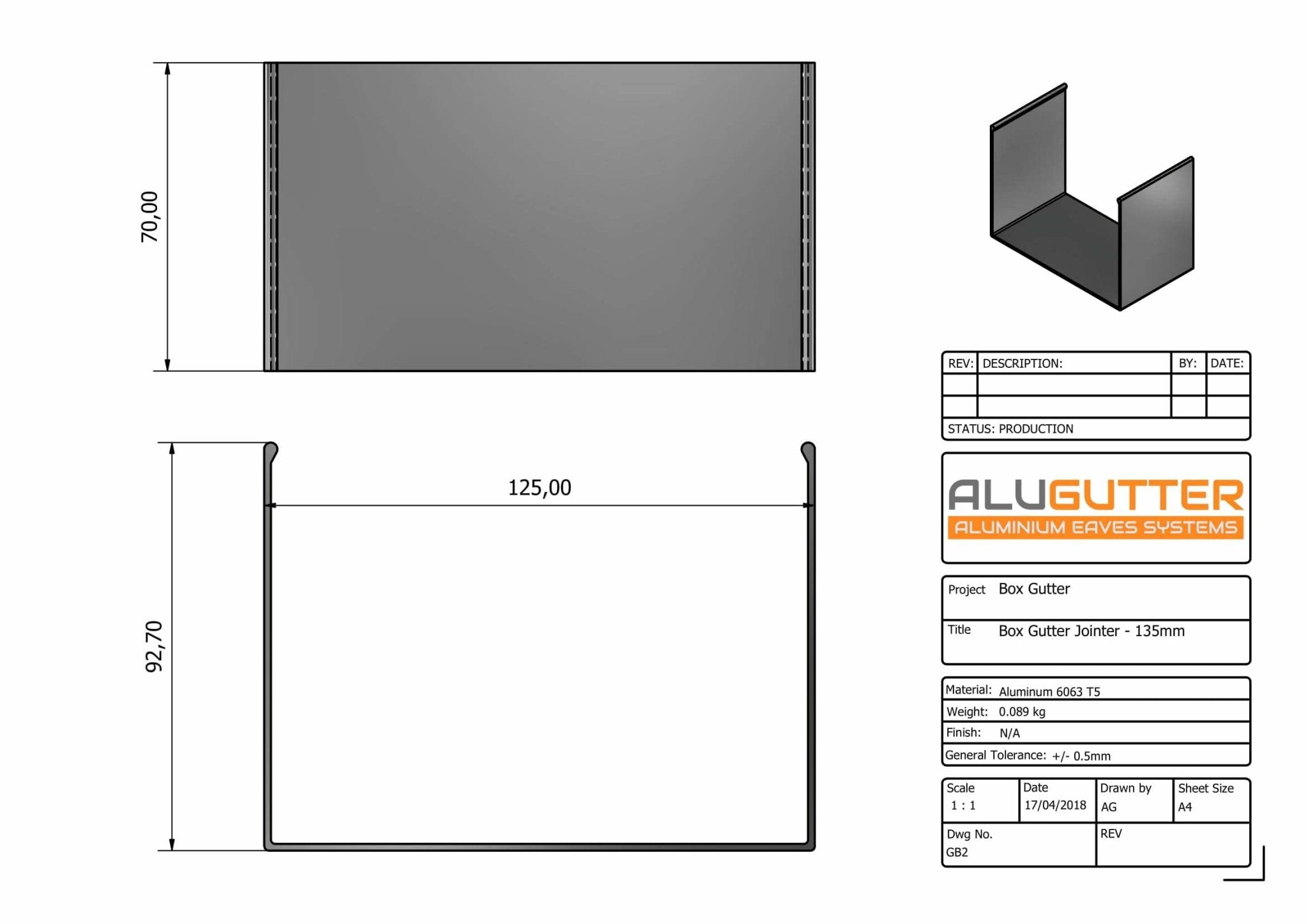

Box Gutters – Modern, square-edged profiles for contemporary builds.

Moulded Ogee Gutters – Traditional aesthetics replicating cast iron.

Calculate Your Gutter and Downpipe Needs

Ensure precise guttering and downpipe quantities with our user-friendly tool. Simply input basic project details, and it auto-calculates your needs—eliminating guesswork, saving time, and preventing mistakes. Designed for everyone, from beginners to seasoned professionals.

Try it now!The Manufacturing Difference: Durability by Design

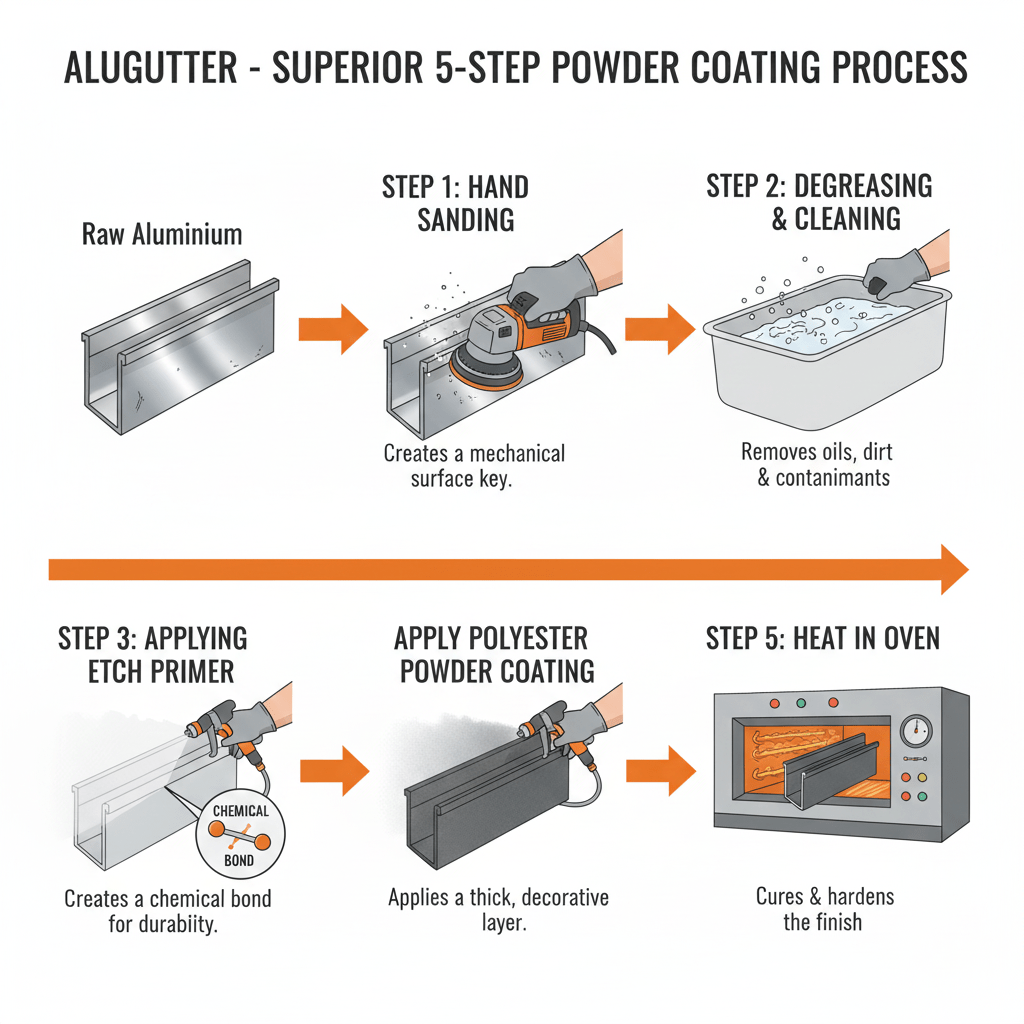

Not all aluminium gutters are equal. While many competitors simply degrease and paint, Alugutter employs a rigorous 5-stage finishing process to prevent paint failure.

- Hand Sanding: Every item is manually abraded to create a superior surface key.

- Chemical Degreasing: Removal of all contaminants.

- Etch Priming: A specialist primer is applied to chemically bond with the alloy.

- Powder Coating: Application of Interpon D1036 architectural-grade polyester powder.

- Curing: Baked for a hard, fade-resistant finish.

This process ensures our aluminium guttering outlasts standard "wash and paint" alternatives.

Read more within our blog.

Easy Install Jointing System

Our unique Snapfit twinseal jointing method facilitates quick, simple, and neat installations. These aluminium gutters suit installation by any tradesperson and perform well in high winds or heavy snowfall, with adjustable bracket spacing for challenging conditions.

Available Finishes

We stock our most popular finishes, Textured Black and RAL 7016 Anthracite Grey, available for dispatch within 5 working days. Custom RAL or BS colours are available upon request to match any building facade.

Fire Rating for Aluminium Gutters

These systems achieve class A2-s1,d0 fire rating, permitting use on buildings of any height.

Maintenance Tips for Aluminium Gutters

Maintenance remains straightforward. Our low-maintenance designs need only occasional cleaning with fresh water and a soft brush. Annually—or twice yearly in marine settings—inspect joint integrity and remove debris.

After extended service, if the polyester powder finish dulls, overpaint with quality metal paint.

In essence, our rainwater solutions provide a stylish, low-maintenance option that surpasses alternatives. With custom choices and support, we address your requirements. Shop the collection, utilise our take-off calculator for estimates, or contact us for tailored advice.

Specification Table

| Aspect | Details |

|---|---|

| Material Types | Gutter lengths: 6063 T6 hardened aluminium extrusion (Half Round, Deepflow, Box). Fittings: LM6 aluminium alloy castings (Half Round, Deepflow); precision cut and welded 6063 T6 (Box). Moulded Ogee gutters: Gravity cast aluminium. |

| Paint Finish | Polyester powder coating using Interpon D1036 external grade architectural powders. Process includes hand sanding, degreasing, etch primer application, followed by powder coating for enhanced adhesion and longevity. |

| Functional Life Expectancy | Exceeds 50 years under normal UK weather conditions. |

| Decorative Life Expectancy | Colour retention over 25 years. |

| Standards | Fire-rated to class A2-s1,d0 (non-combustible). Compliant with BS EN 12020 (extrusions) and relevant UK building regulations for rainwater systems. |

| Lead Times | Stocked items: within 5 working days for dispatch. Non-stocked items: within 10 working days. Bespoke products: within 15 working days; contact for specifics. |

- Wide range of profiles, sizes, and colours.

- Manufactured in-house and supplied direct at low factory prices.

- Suitable for all environments, outlasting other materials.

- Technical team available for advice.

- Resistant to rust, rot, or brittleness; Snapfit twinseal jointing ensures simple, quick, tidy installations.

- Designed for leading drainage flow performance.

- Produced from marine-grade alloys.

- Polyester powder coated in fade-resistant architectural-grade paint for low maintenance.

- Fully sustainable and infinitely recyclable.

- Applicable to domestic, commercial, and industrial settings.

- Short lead times - within 5 working days for stocked items, within 10 working days for non-stocked items, and within 15 working days for bespoke products.

- All systems fire-rated A2-s1,d0 for use on any building height.

- Designed and manufactured in the UK.

We offer our various styles of aluminium guttering in a variety of standard colour options. Textured black and RAL 7016 anthracite grey are very popular colours and are stocked items in most ranges. Stocked items are available on a shorter 5 working day lead time.

If the colour you require is not within our standard list please contact us for pricing. We can provide our products polyester powder coated to any RAL or BS colour reference.

Guttering with Exceptional Durability

Our systems prioritise resilience, using robust base materials and tough coatings to withstand elements better than alternatives. For gutters requiring infrequent replacement, this material excels.

How Long Do Aluminium Gutters Last?

Produced from marine-grade alloys and exterior-grade polyester powders, these will not rust, rot, or crack like iron or steel. The paint ranks among the most durable decorative options. Functional life expectancy reaches approximately 50 years, with coatings providing decorative finish for over 25 years under minimal maintenance.

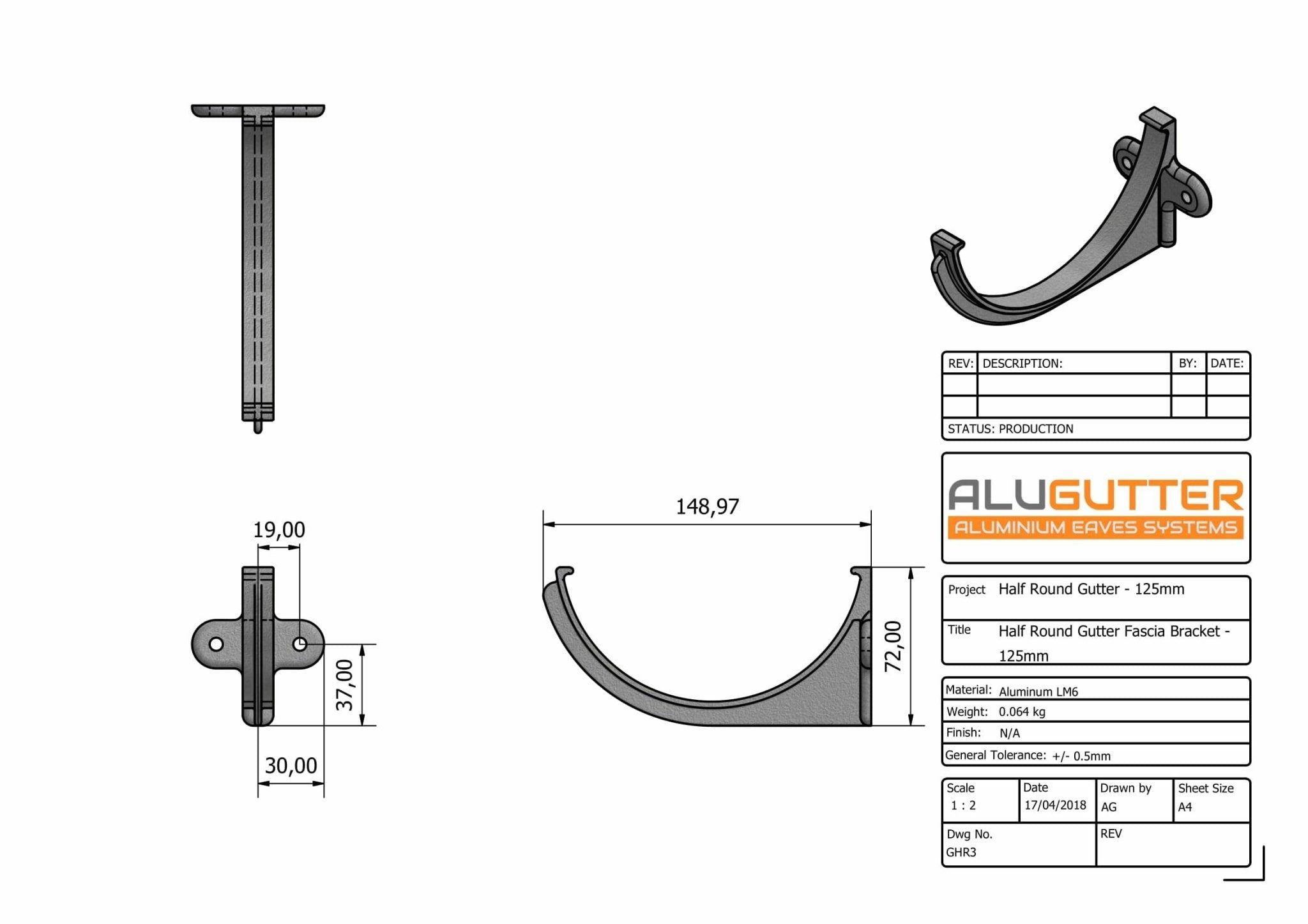

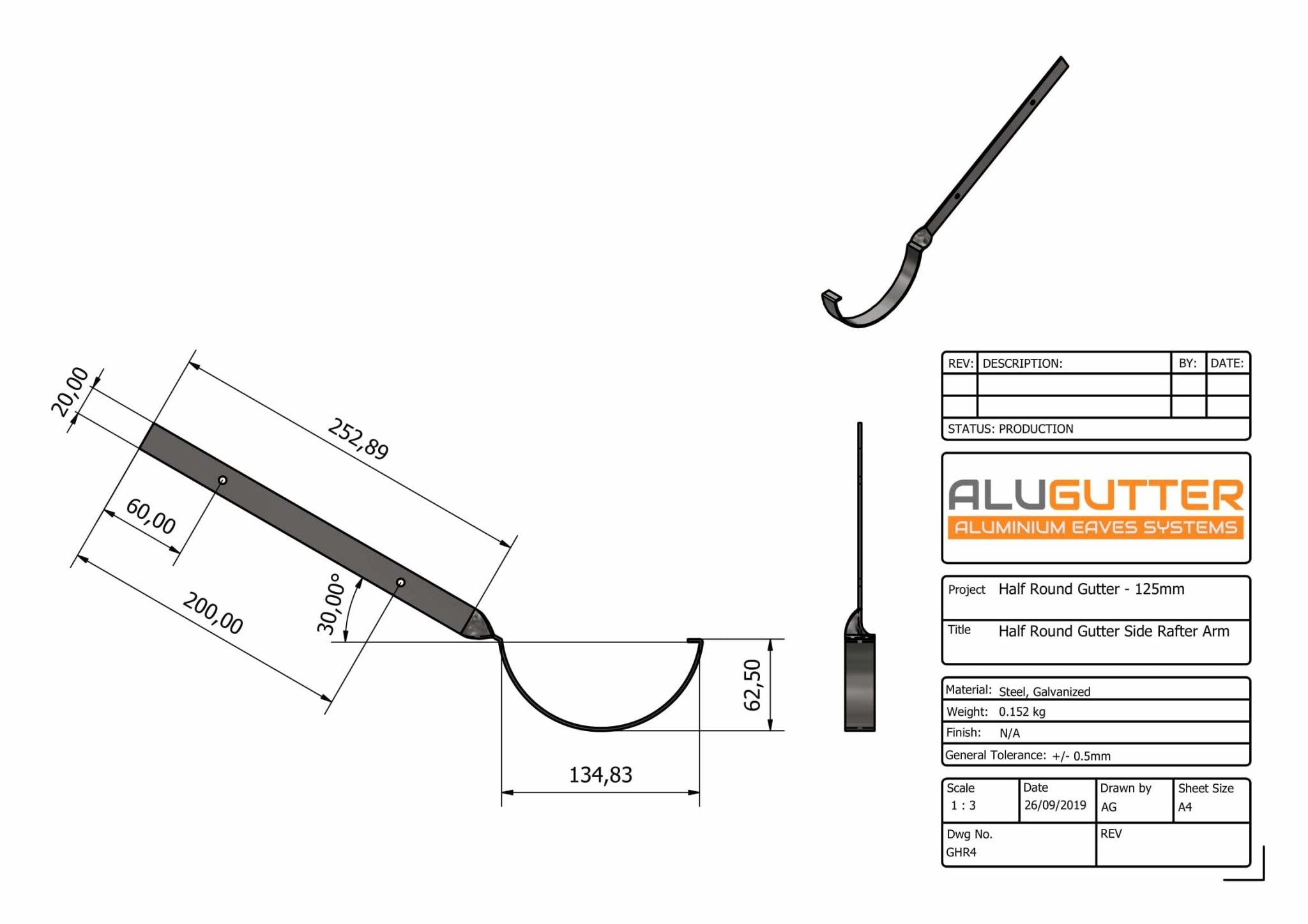

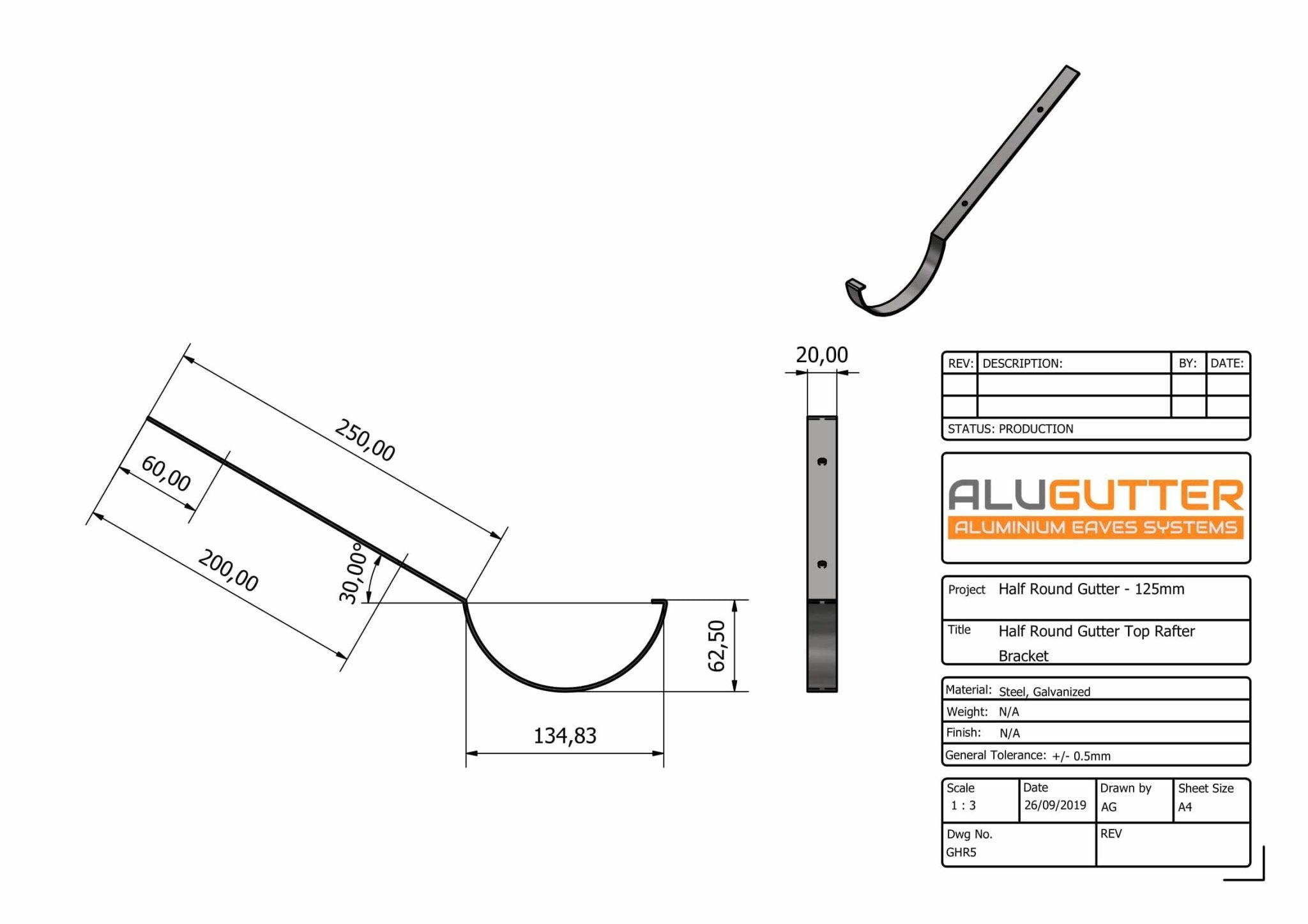

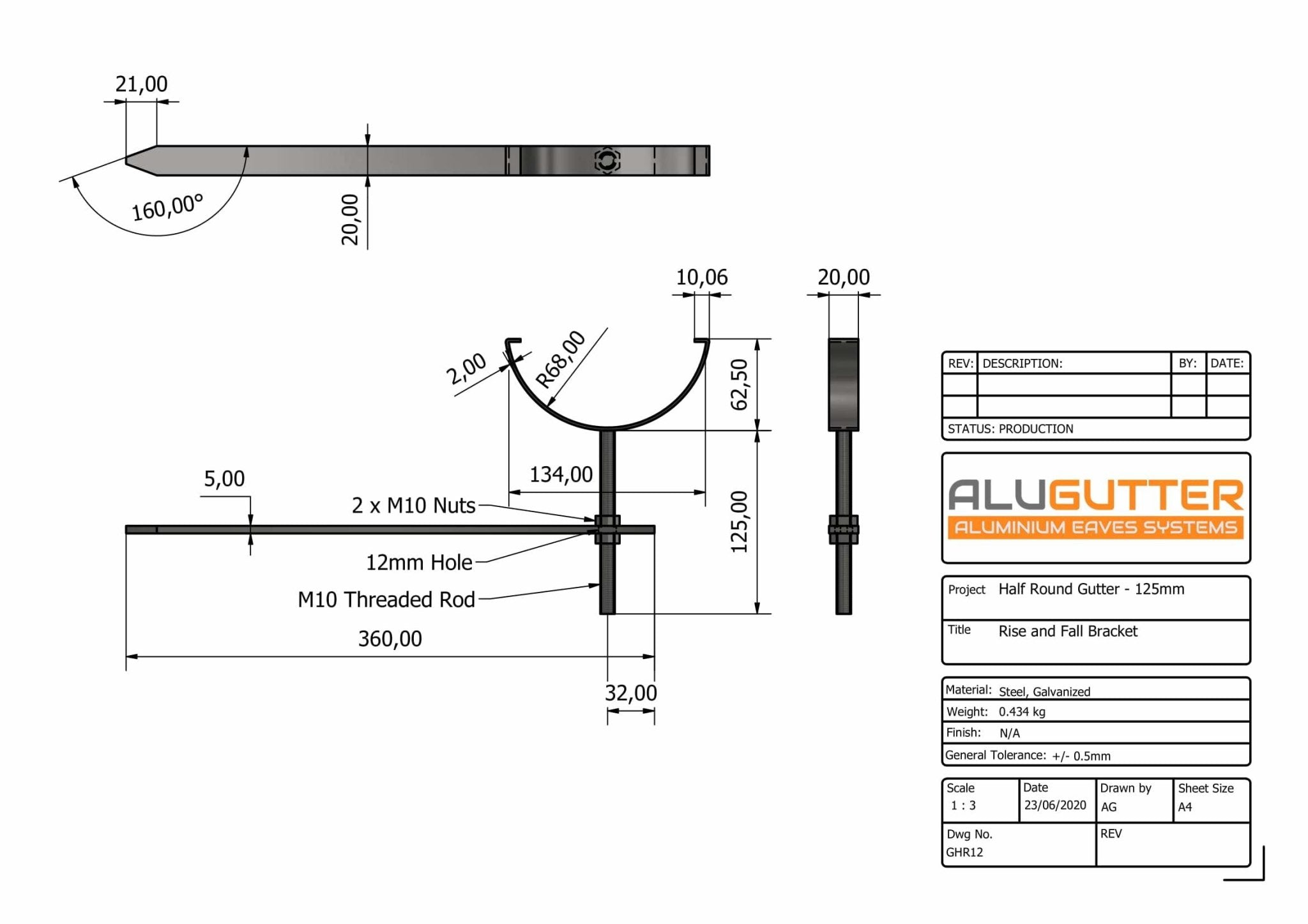

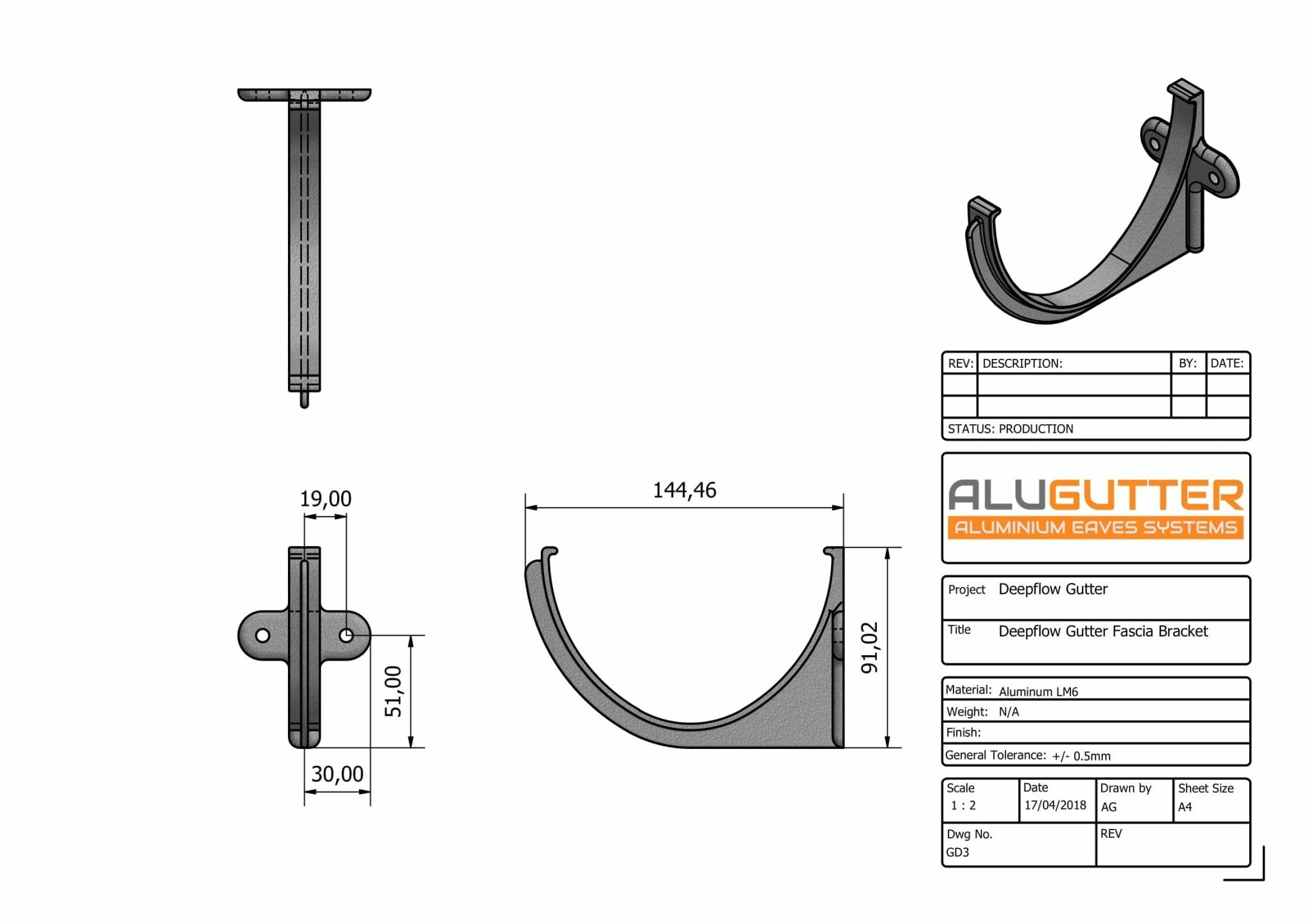

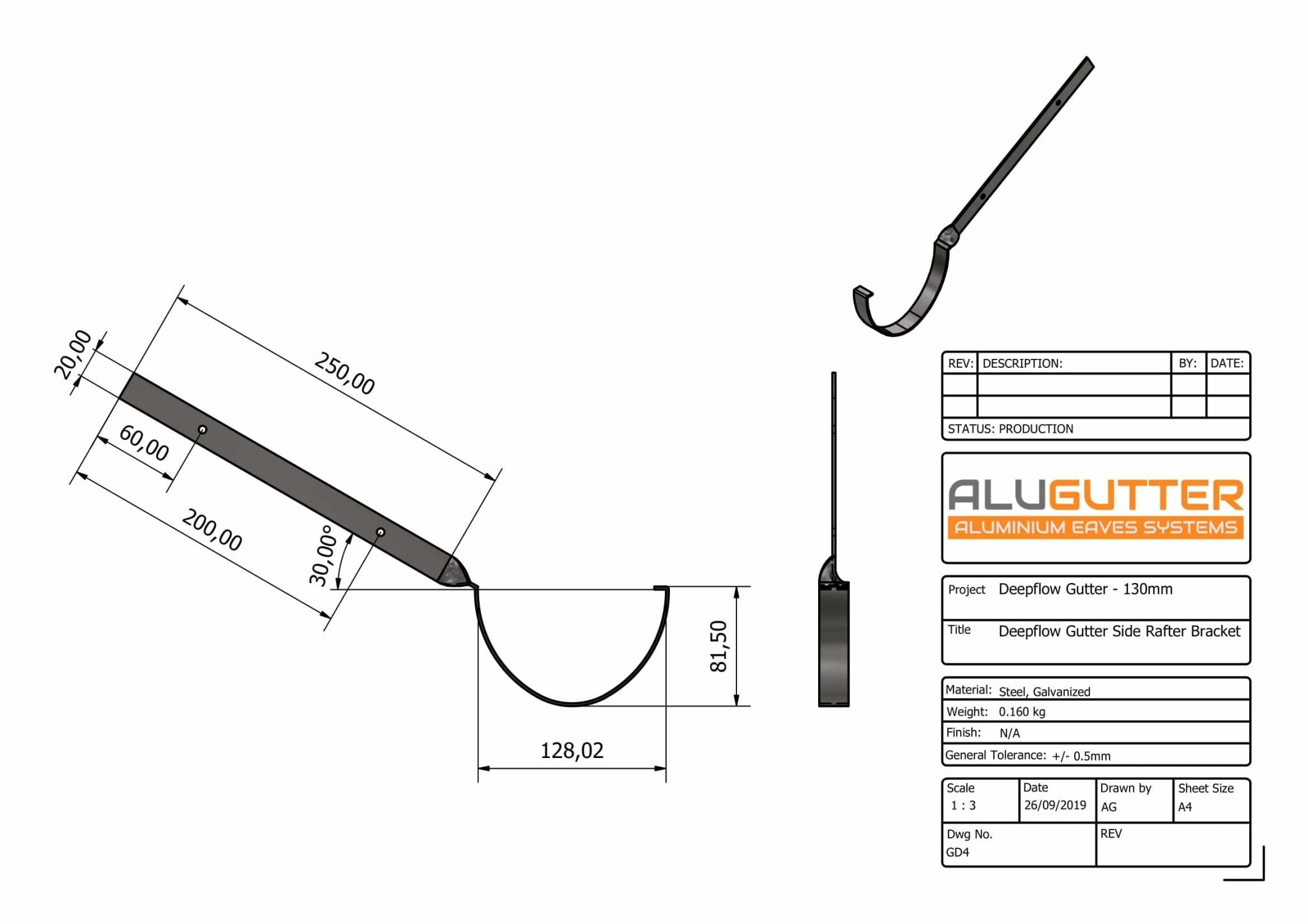

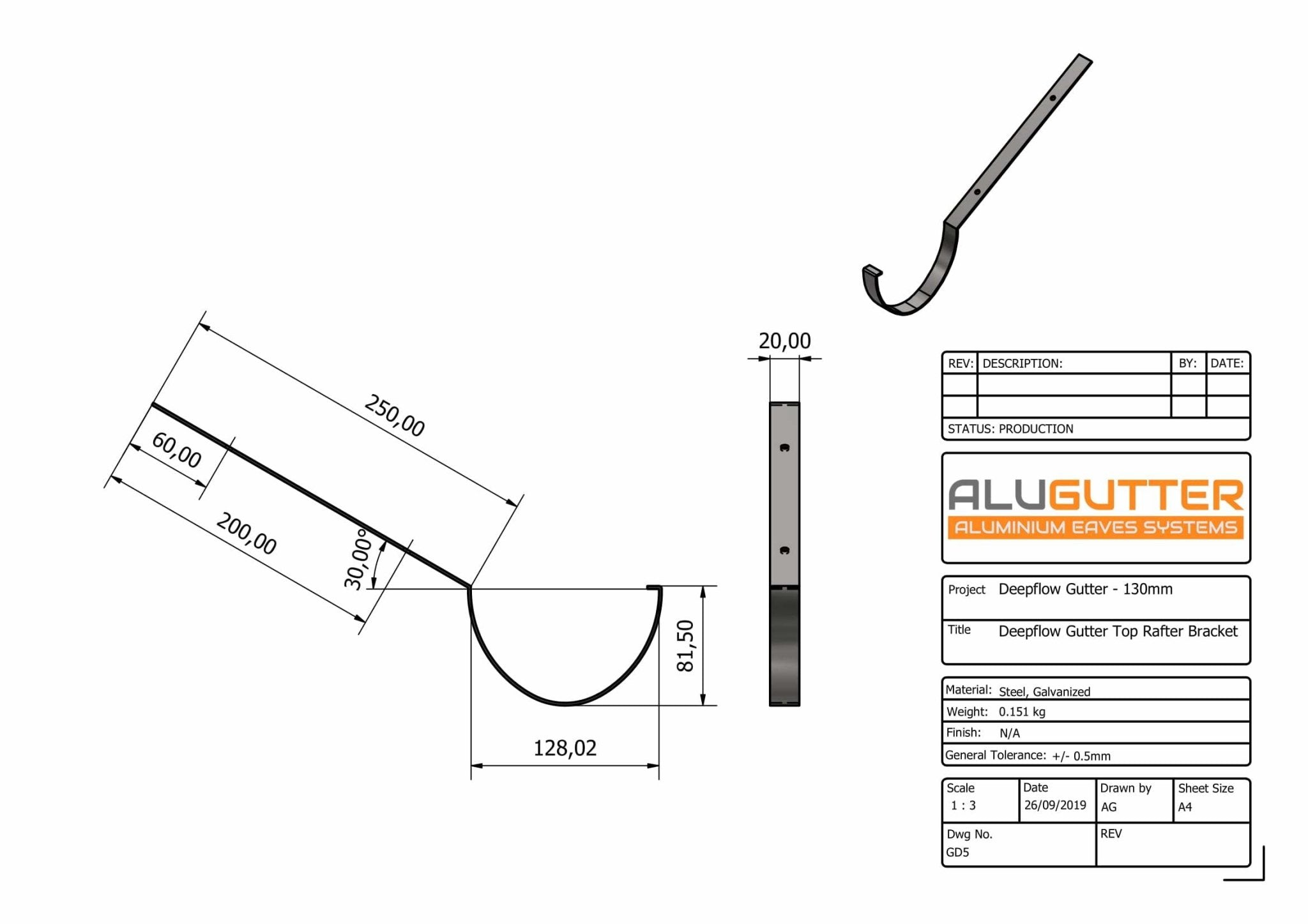

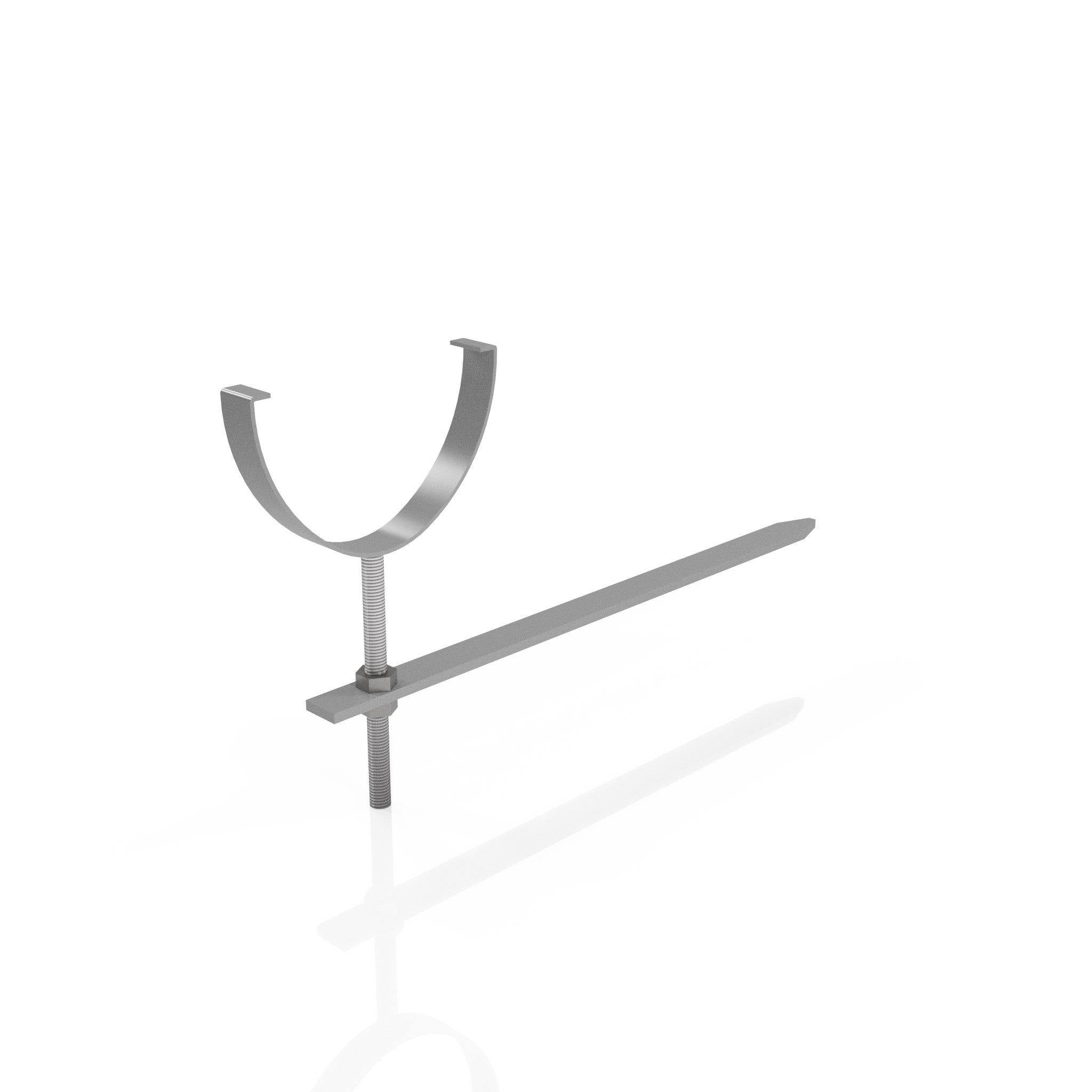

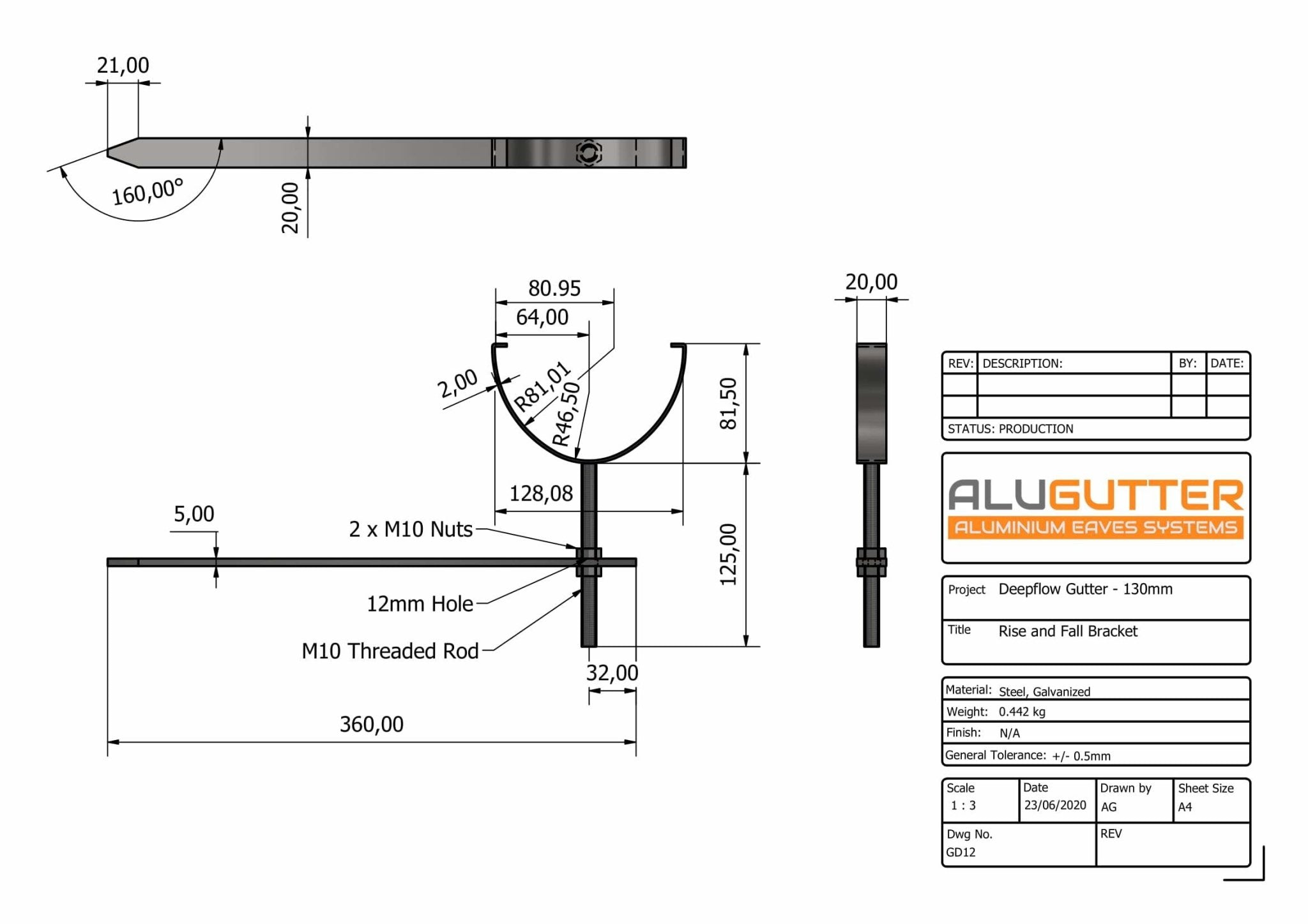

Fascia Bracket Spacing

Brackets should space at maximum 1 metre. In windy or snowy areas, reduce spacing. Options include fascia board attachments, rafter arm fixings, and brickwork spikes.

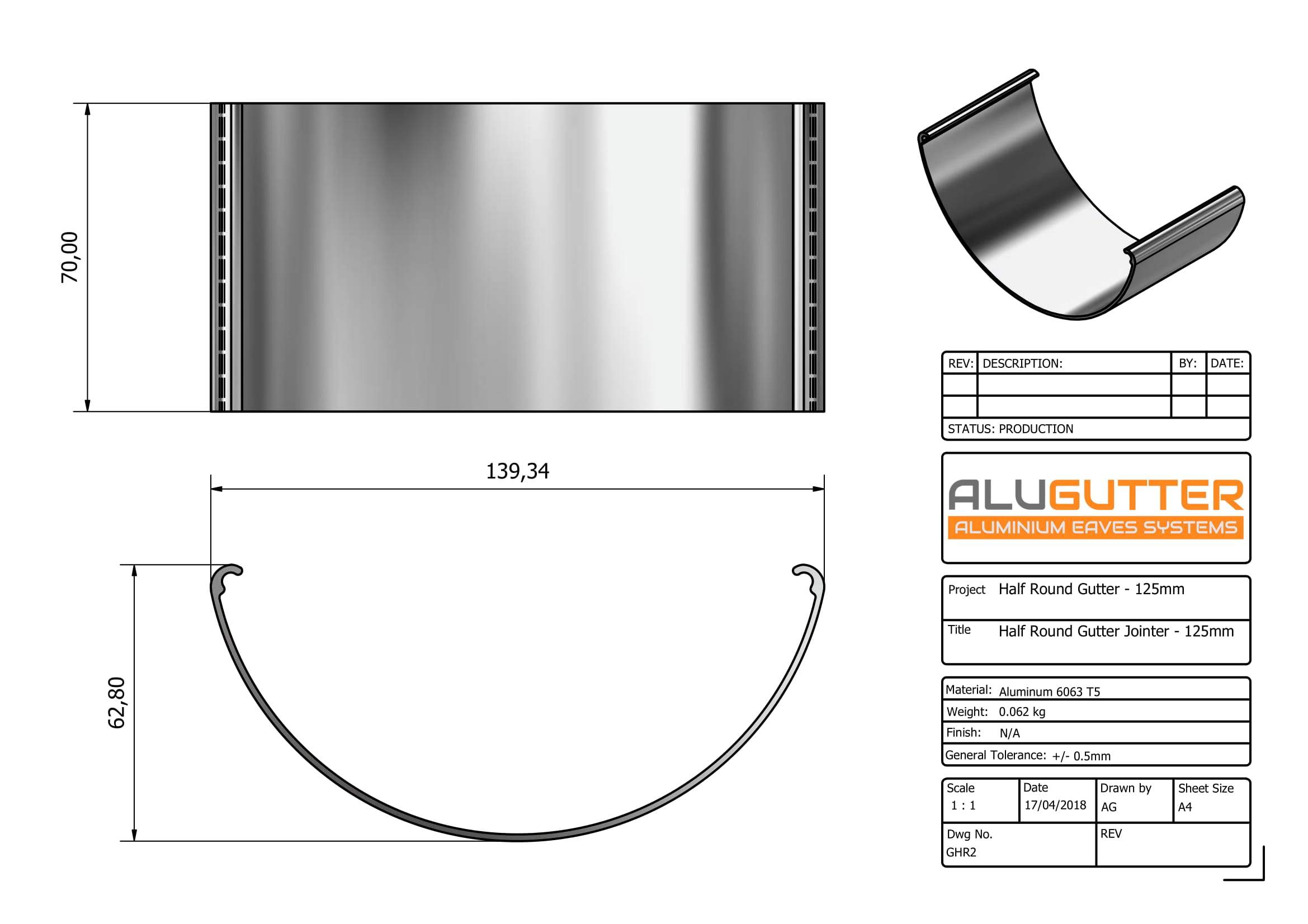

Gutter Joints

The Snapfit twinseal method simplifies installation: apply high-performance silicone sealant (code SU1) between foam spacers in jointers, outlets, and angles, then click together. For Moulded Ogee, male ends slot into sections, sealed with SU1 and anchored via nuts and bolts (code SU5).

How to Install Aluminium Gutters

Any tradesperson can install using mitre or skill saws with metal blades for cuts.

For a more detailed look into how our individual systems are installed, please take a look at our installation videos or download our installation guides.

Product Materials Specification

- Extruded Material: Aluminium Grade 6063 T6

- Cast Material: Aluminium LM6

- Paint: Architectural Grade External Polyester Powder Paint

Example Gutter System Design Specification

311

ALUMINIUM EAVES GUTTERS

Manufacturer: Alugutter, 1 Stratton Way, Elms Farm Industrial Estate, Bedford, MK41 0NG.

Tel: 01234 958695

Reference: Half Round / Deepflow / Box / Ogee rainwater system

Flow Performance: As manufacturers literature.

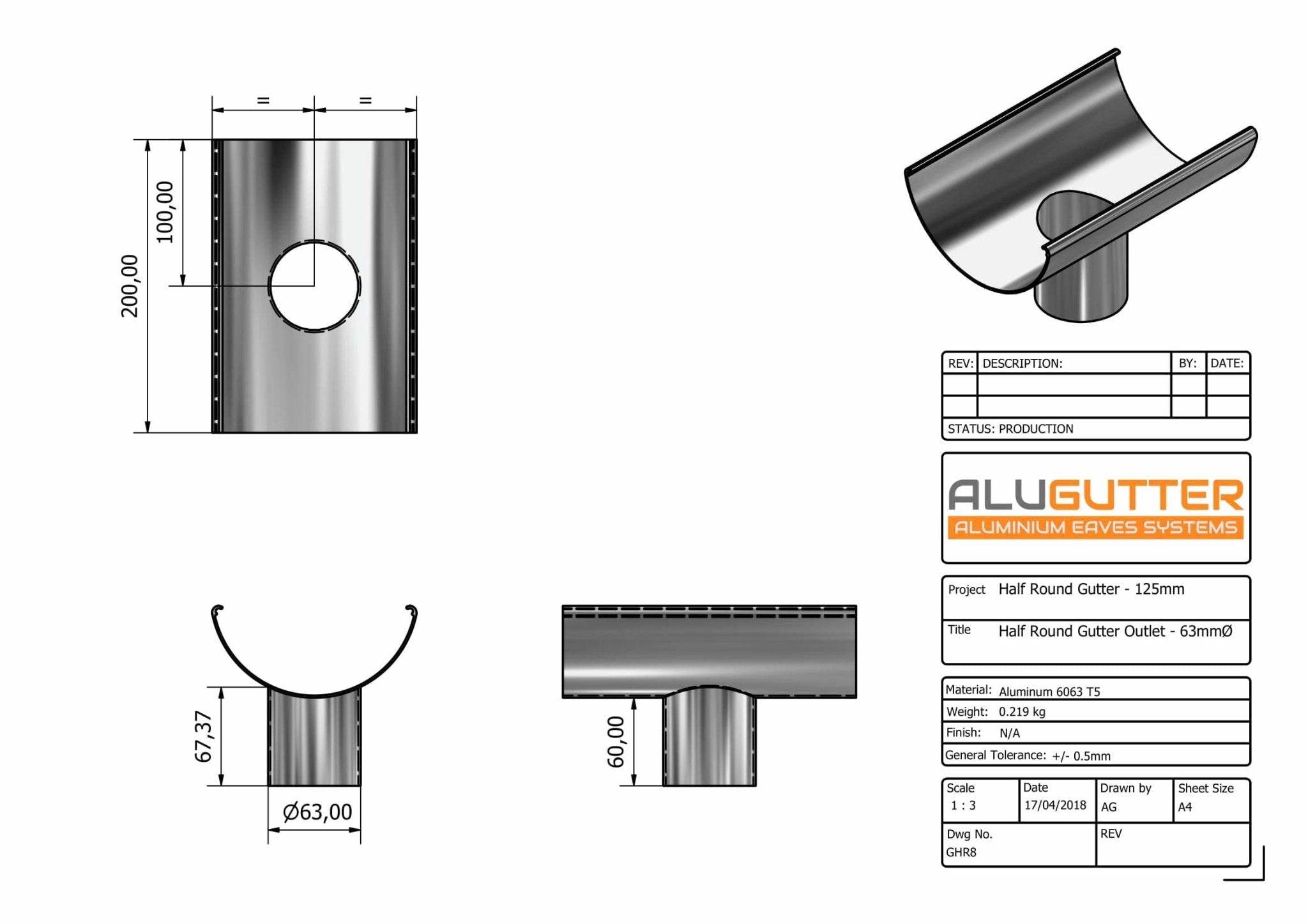

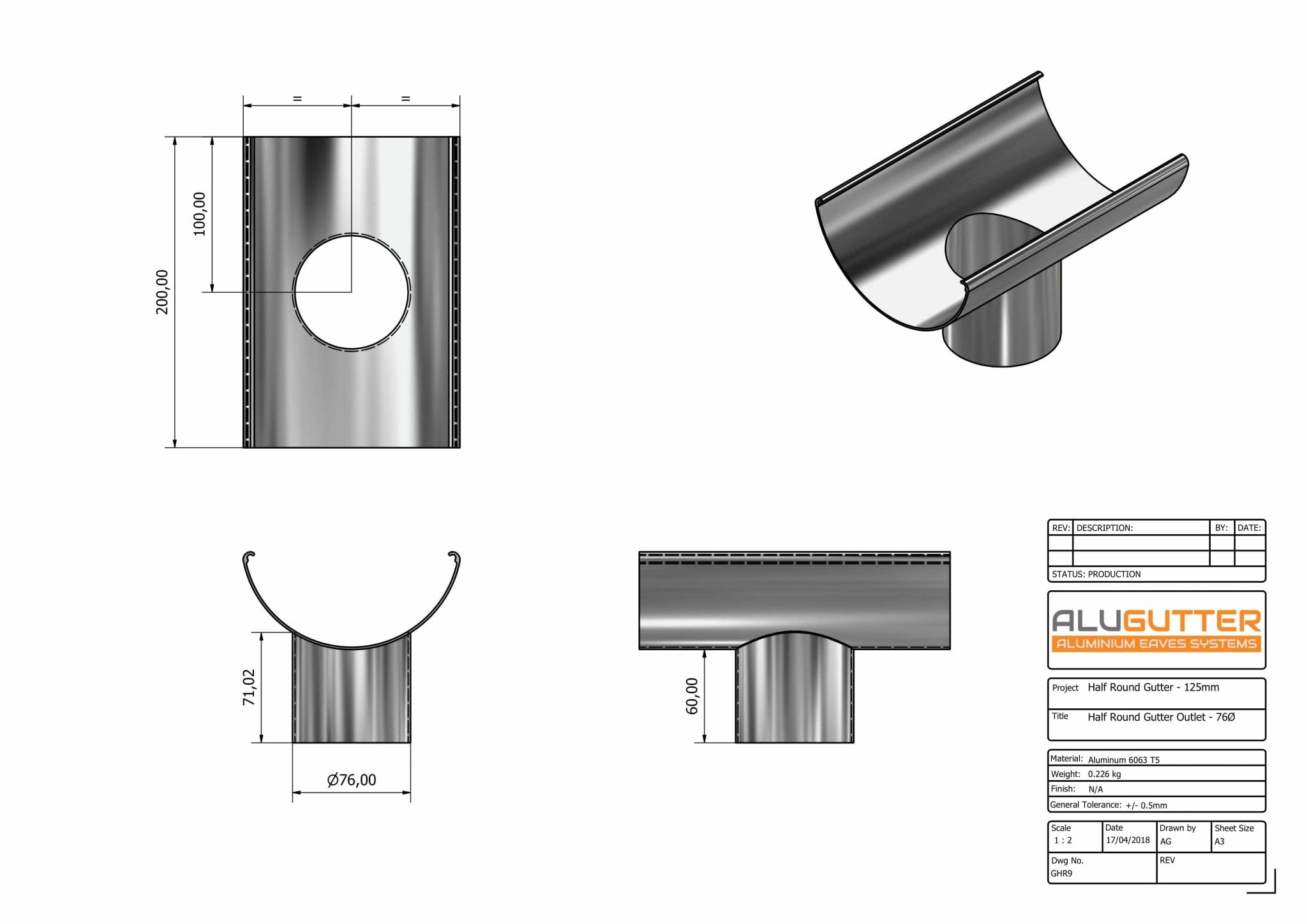

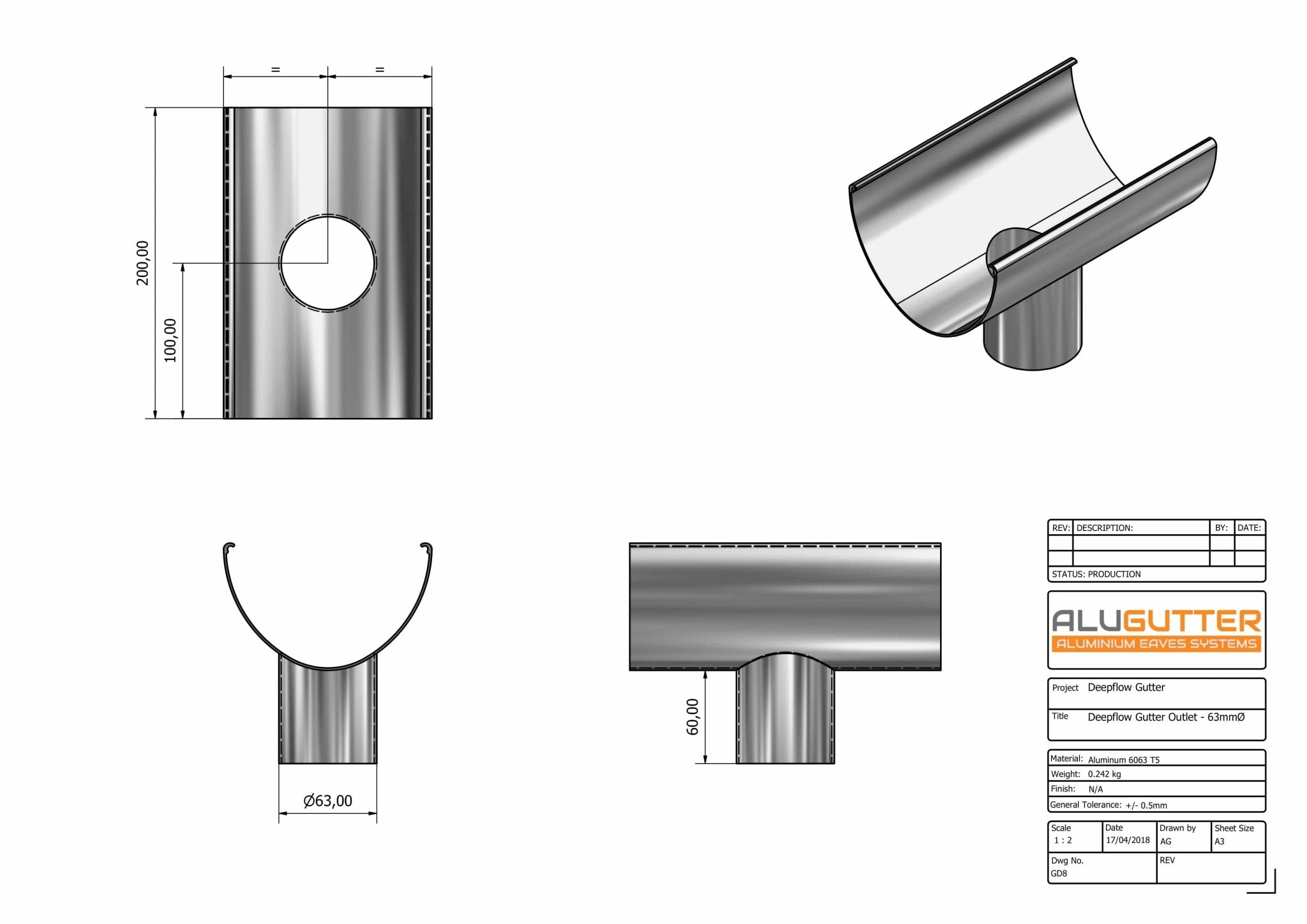

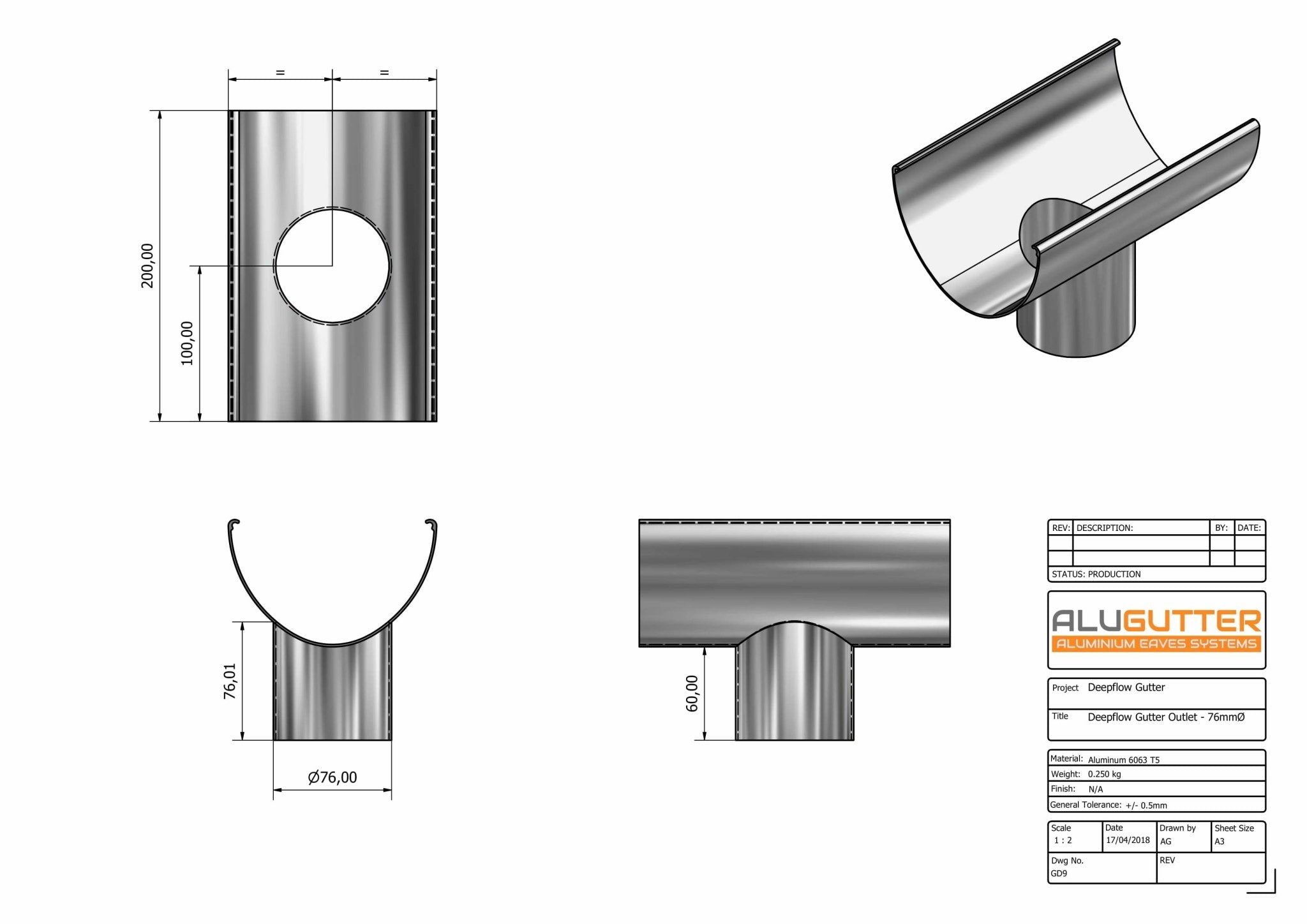

Outlet Size: 63mmØ / 76mmØ / 72x72mm

Type / grade: Marine grade extruded aluminium to BS EN 755-2:2008

Finish: Polyester powder coated to BS EN 12206-1:2004

Colour: TBC

Functional life expectancy: 50 years

Jointing: As per manufacturers instructions

Fixing: BS EN 1462:2004 Class H, external fascia brackets at 1m centres. Fixed with Alugutter austenitic stainless steel No. 12 x 30mm Pozi Pan screws.

Product Specification Sheets

Individual product specification sheets are available for download or can be customised and created using our specification tool.

CE Marking

CE Marking is not required for these products, as no harmonised European standard exists, prohibiting CE marks.

Gutter Maintenance

Powder coated aluminium guttering systems have a proven track record for being extremely durable whilst requiring little maintenance. This is one of the reasons they are widely specified for high end domestic applications.

Aluminium eaves systems are also commonly seen on high rise buildings, office blocks, schools, churches and retail units as regular cleaning is often impractical due to costs and accessibility. Our systems will offer a significant saving on maintenance costs when compared to other guttering materials.

Similar to aluminium windows and other painted surfaces, periodic cleaning of our aluminium gutters should be undertaken to keep the system looking fresh and prolong the life of the paint.

In most cases, rainwater will wash away light grime build-up. To wash away pollutants or salt in coastal environments, polyester powder coated surfaces only require fresh water and a soft brush to bring the original appearance back.

Once a year, or twice in a marine environment, we recommend that the gutter system is cleaned and joint integrity is checked. Any collected gutter debris should also be removed.

Cleaning of gutter systems can often be undertaken at ground level by specialist gutter cleaning companies. Often window cleaning services will also offer this type of service.

Can Aluminium Guttering be Painted?

Following many years of service, once the original polyester powder paint finish loses its original lustre, the painted surfaces can be overpainted using a good quality metal paint.

Surfaces should be first be sanded down with a light abrasive to remove any of the old loose paint. The system can then be cleaned with a soap and water solution in preparation for the primer.

Apply a good quality metal primer as this is the basis for a long durable finish. Leave the primer to dry and then apply the paint as per manufacturer’s instructions.

Top tip: Check the weather forecast! Ideally painted surfaces will need at least 3 days to dry.

Aluminium Gutter Supplies UK

We supply our guttering and downpipe systems throughout the UK and will deliver direct to your chosen address (UK Mainland) via courier services. For deliveries outside of mainland UK please contact us for pricing.

Aluminium Gutters and Fascias

In order to complement the longevity and look of our aluminium guttering systems, we also offer aluminium fascia and soffit systems in various styles and colours.

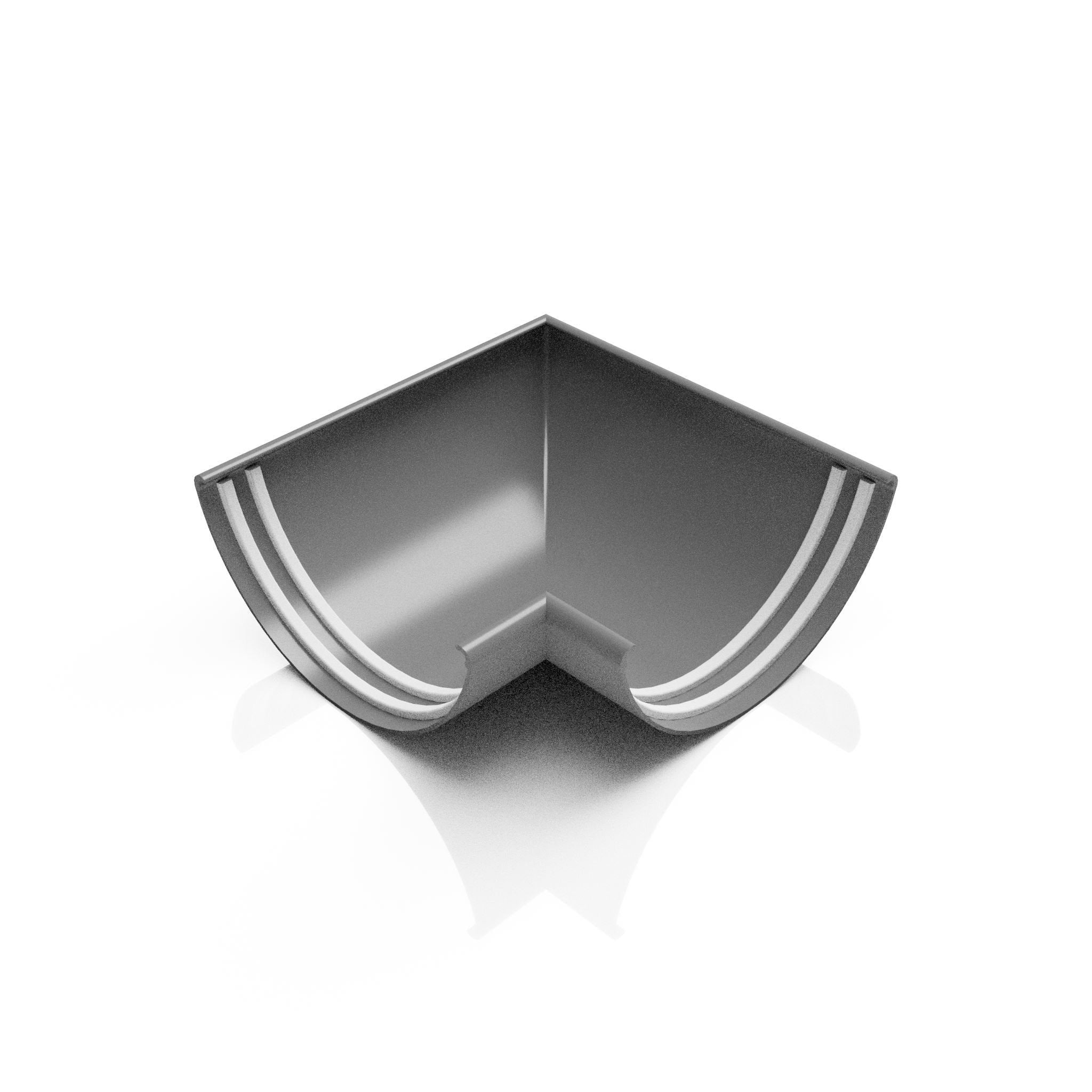

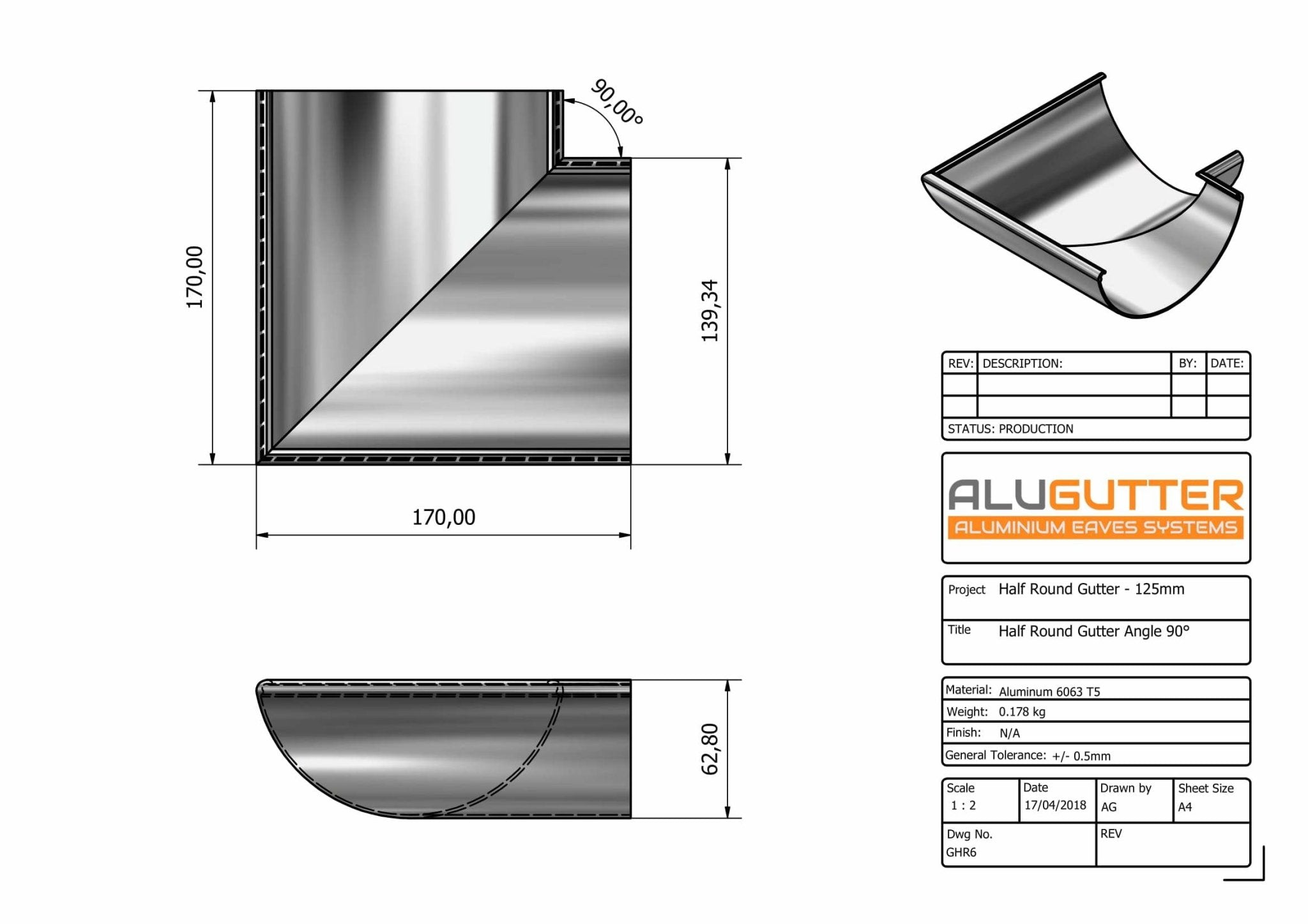

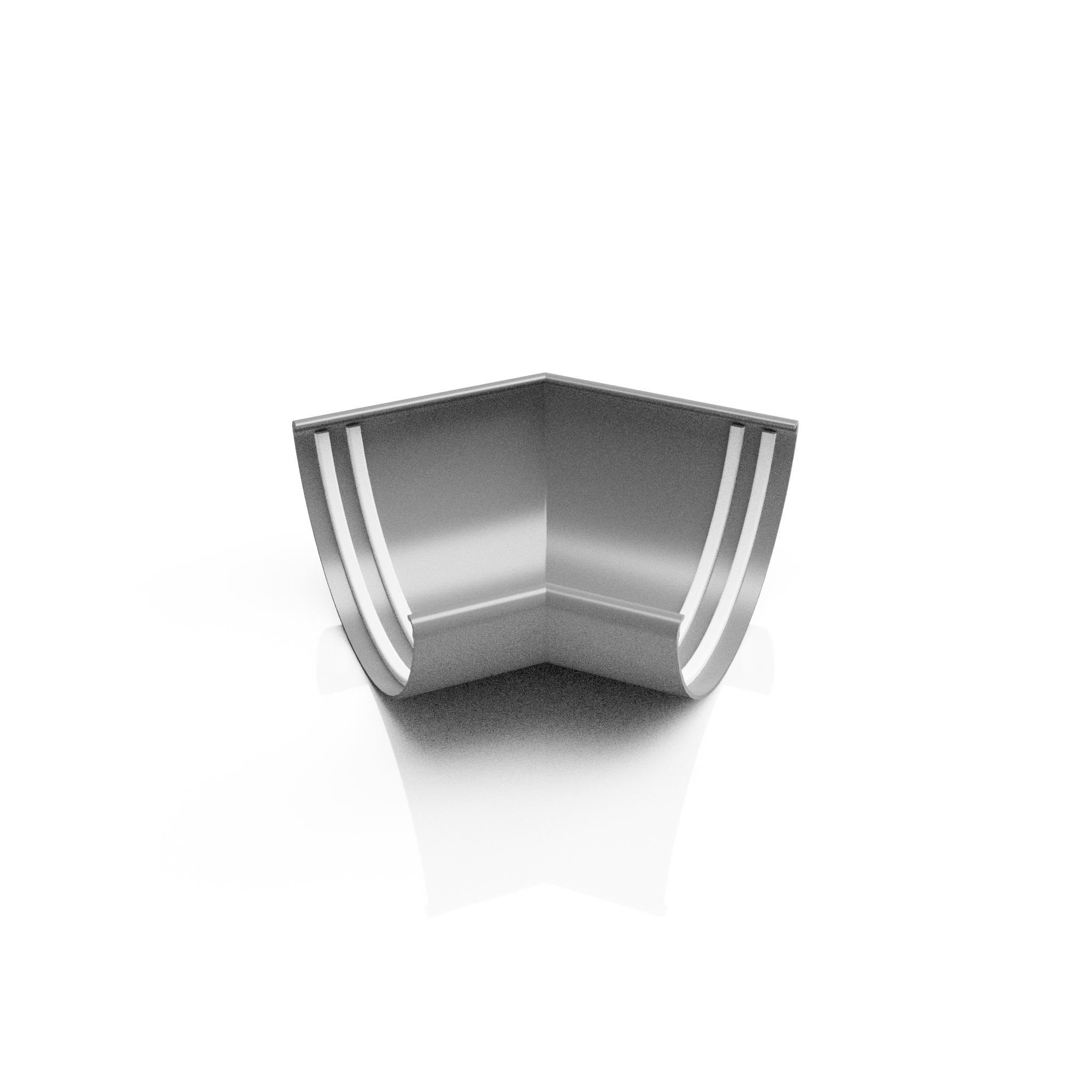

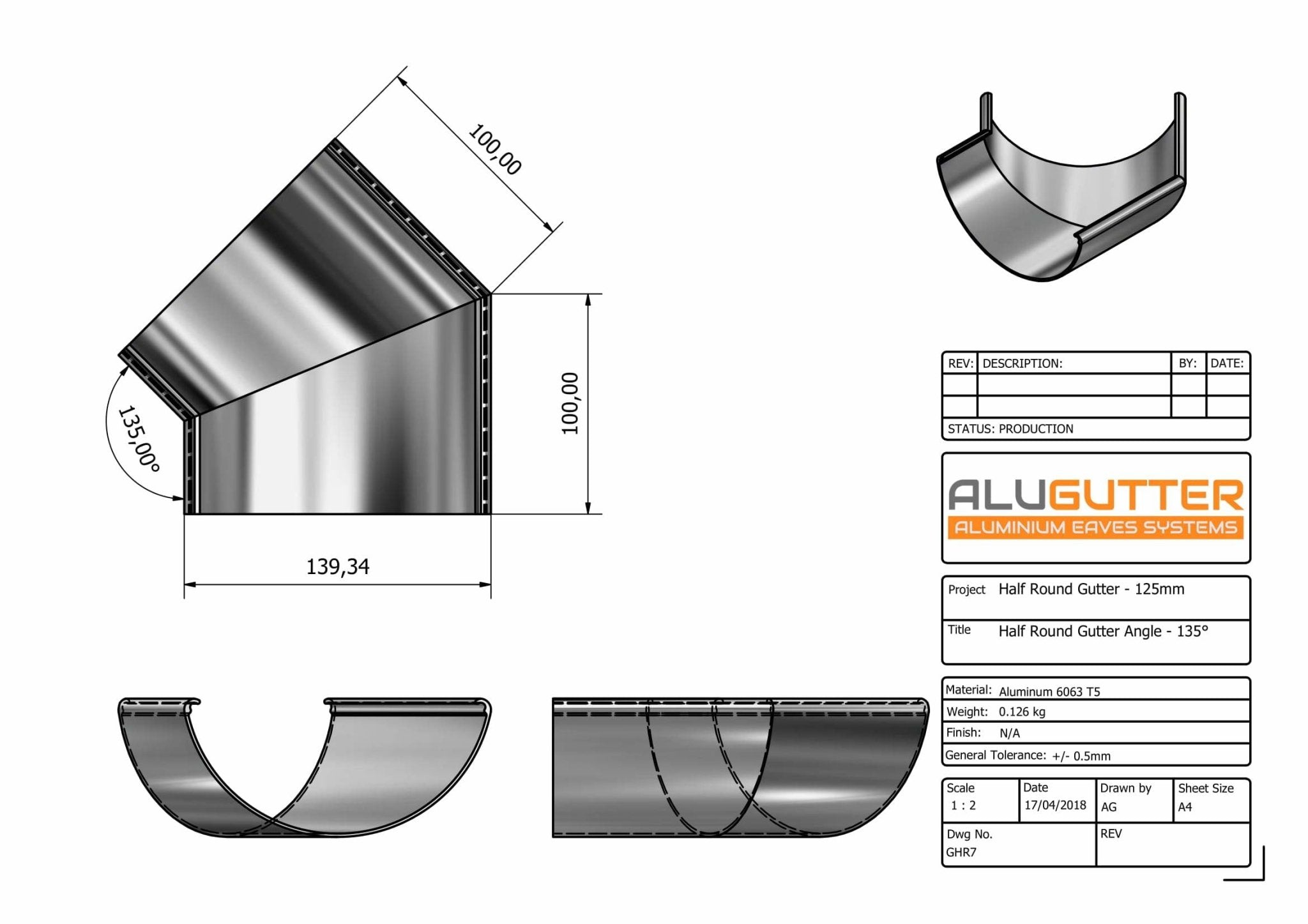

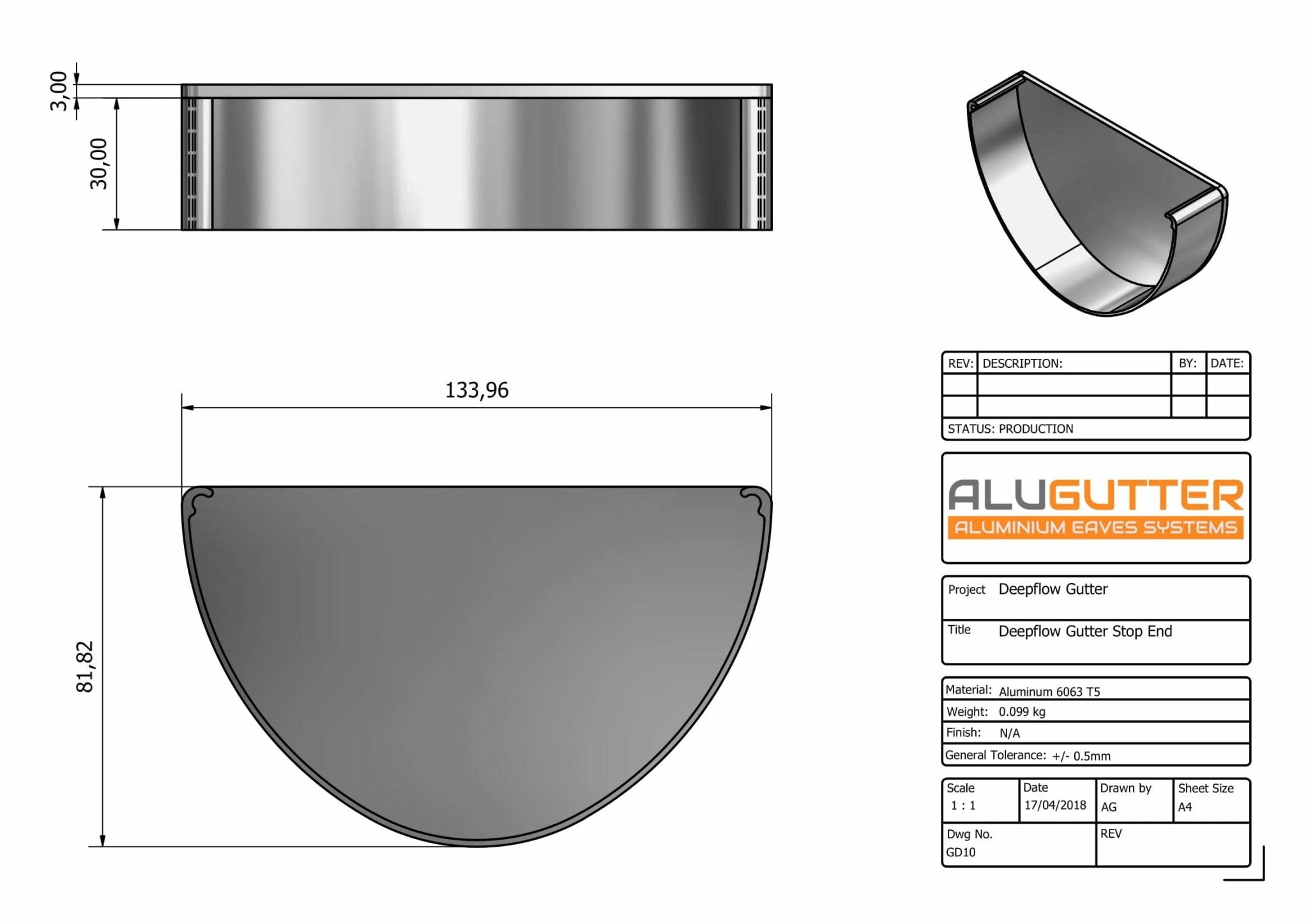

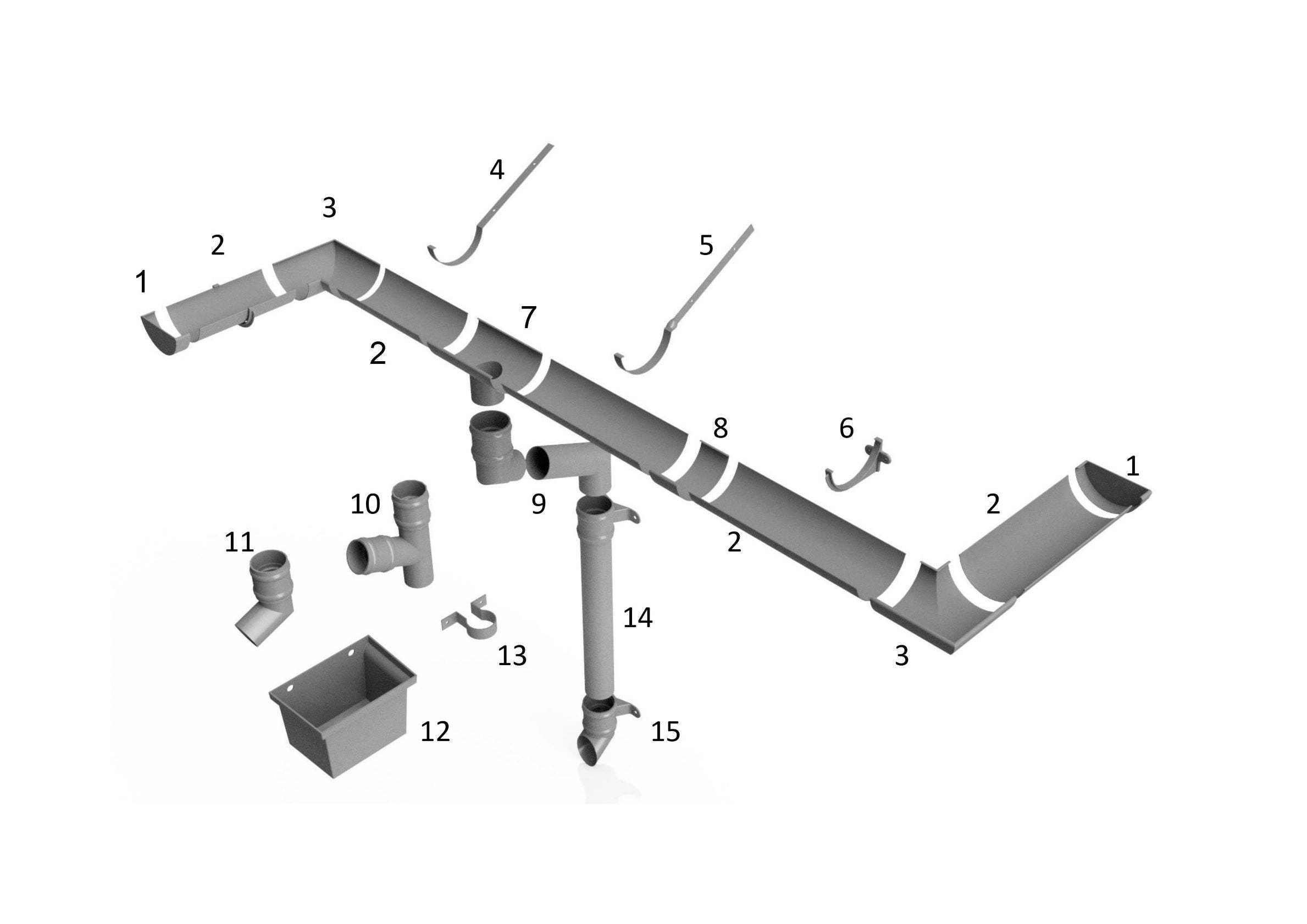

Guttering System Component Names

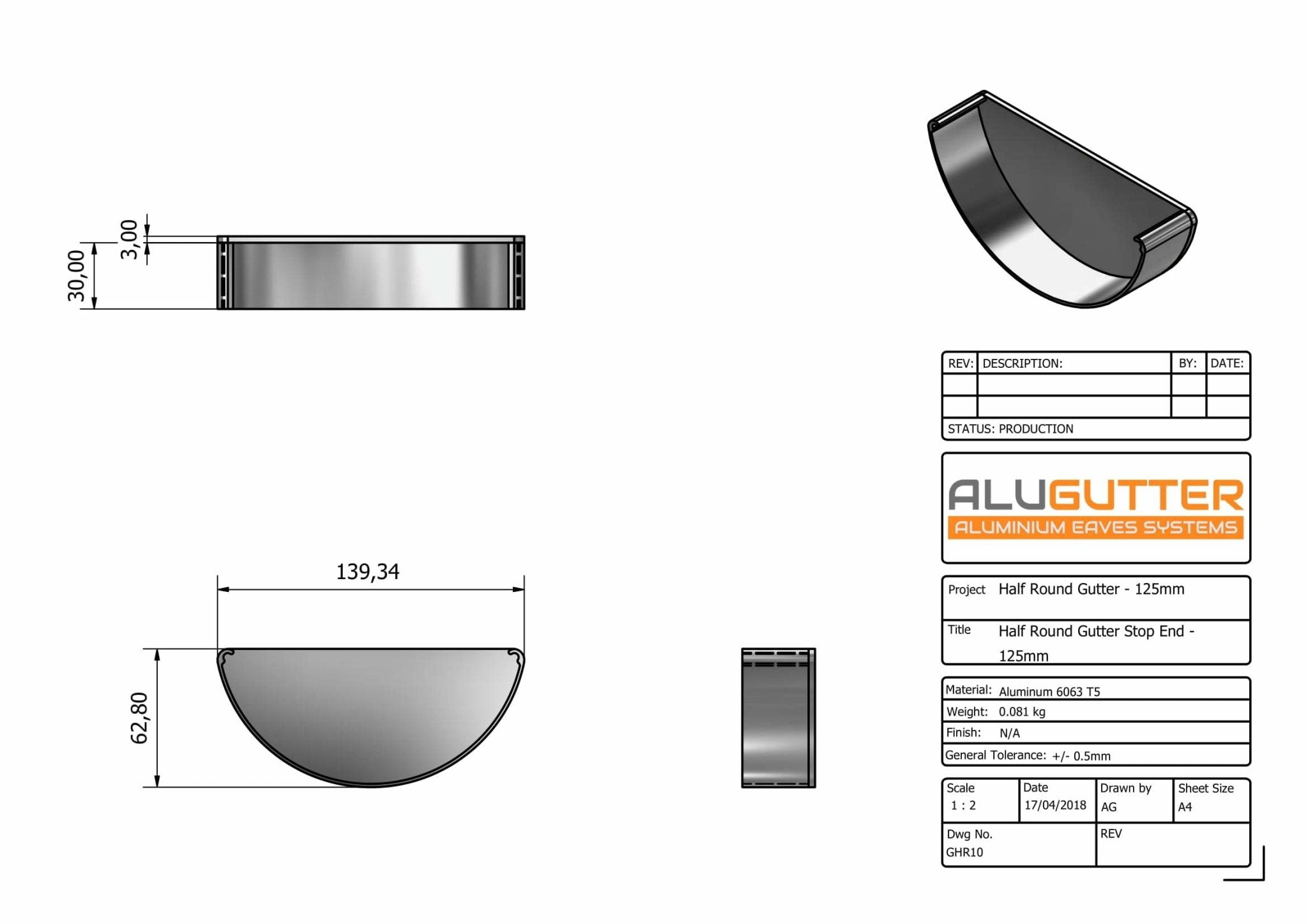

1) Stop End

2) Gutter Length

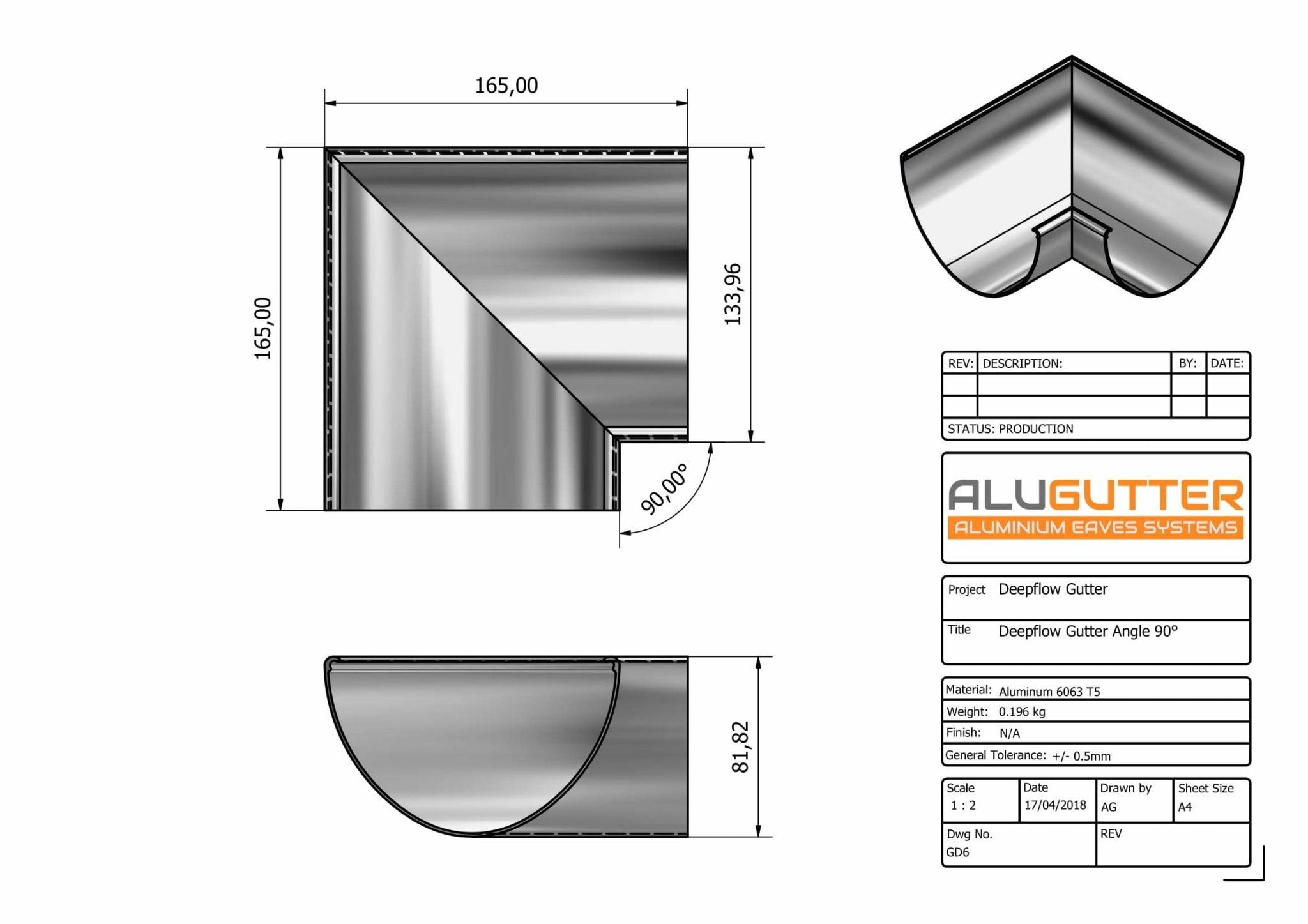

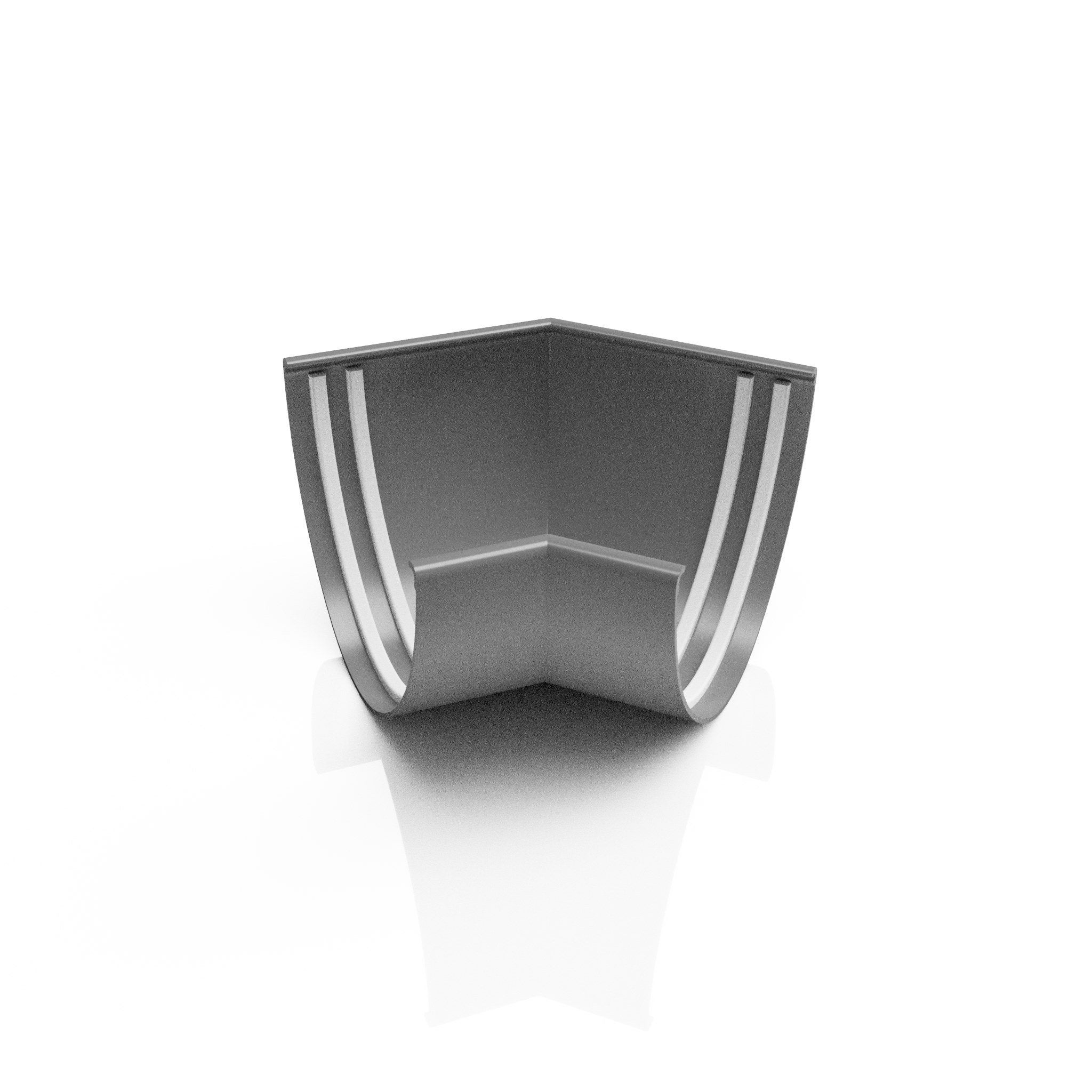

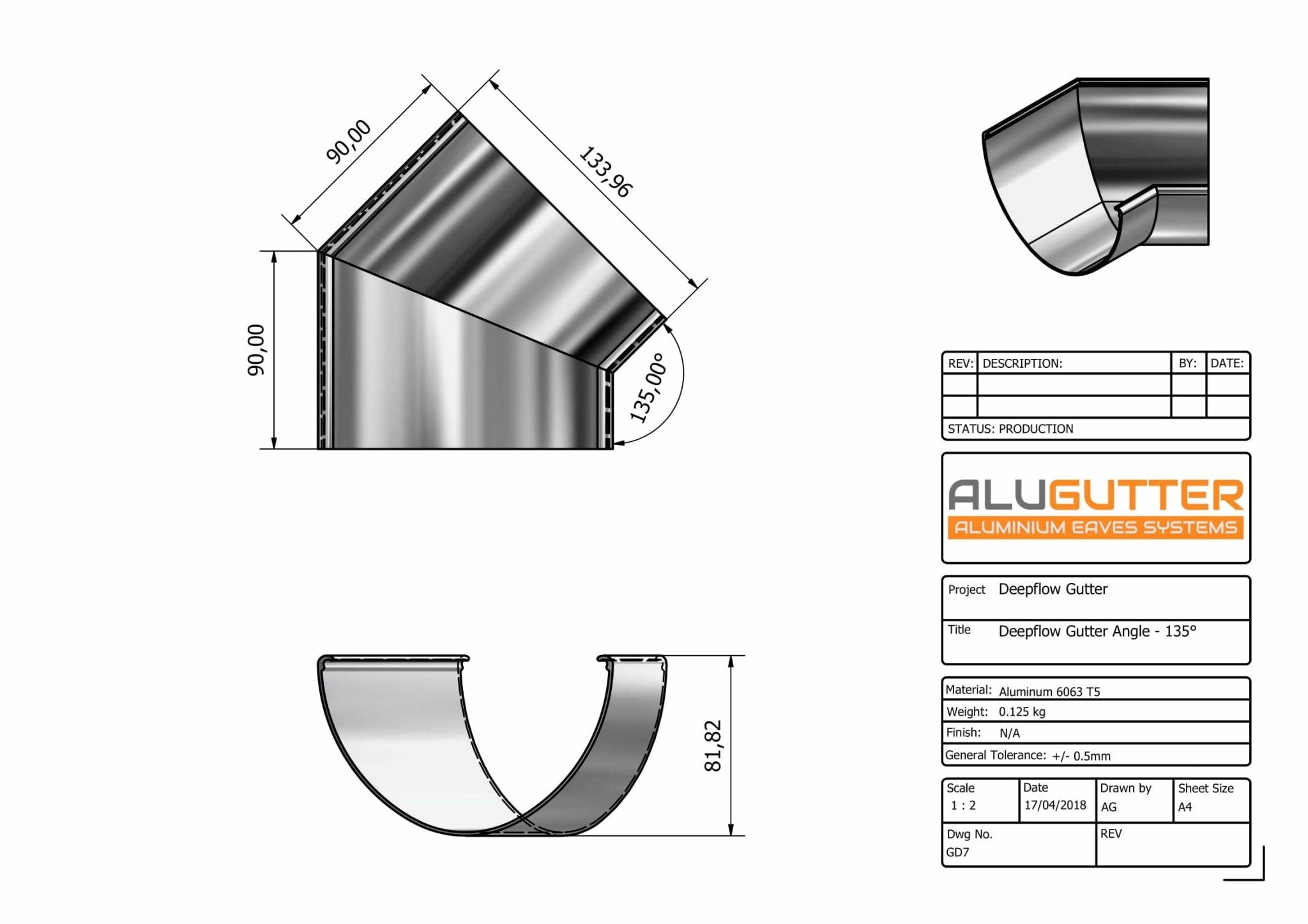

3) Gutter Angle

4) Top Rafter Arm

5) Side Rafter Arm

6) Fascia Bracket

7) Gutter Outlet

8) Gutter Jointer

9) Adjustable Swanneck

10) Pipe Branch

11) Pipe Bend

12) Hopper Head

13) Pipe Clip

14) Pipe Length

15) Pipe Shoe

Blog posts

View all

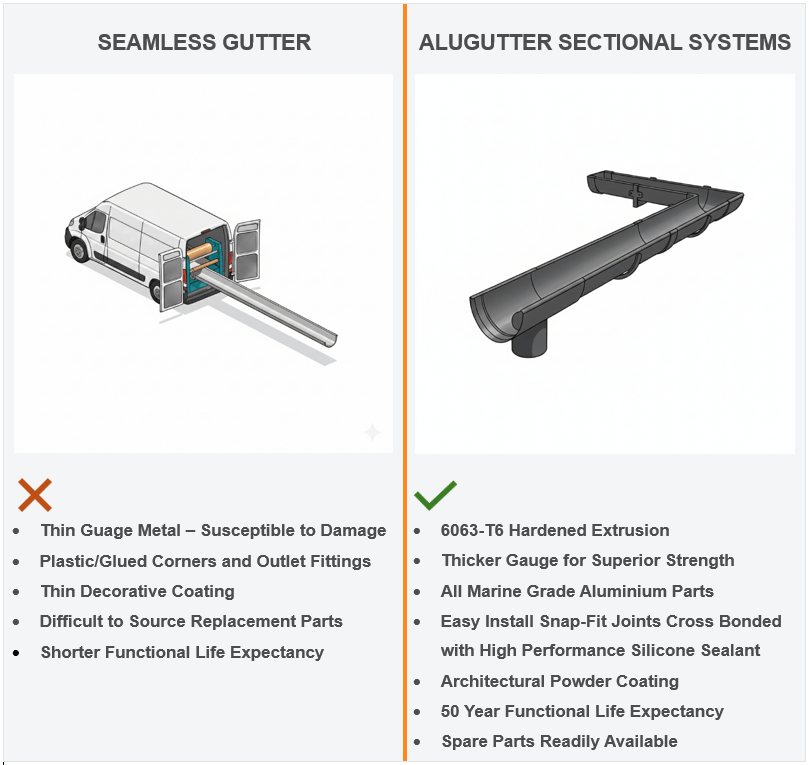

Seamless Guttering vs. Sectional: Why Material Grade and Manufacturing Methods Matter

Discover why sectional aluminium gutters manufactured from high-grade 6063 T6 hardened extrusion offer superior durability and longevity compared to site-formed seamless alternatives. While "seamless" systems are often marketed as leak-proof, they frequently rely on thin-gauge metal and inferior PVC joints. In this technical guide, we compare material thickness, the importance of our hand-sanded Interpon D1036 powder coating process, and why a factory-engineered sectional system is the professional choice for the UK climate.

Alugutter's 5-Step Powder Coating Process: The Key to Lasting Aluminium Gutter Finishes

At Alugutter, we refuse to compromise on quality. Learn precisely how our 5-step in-house process—from hand sanding to oven curing—ensures the decorative coating on your aluminium rainwater system is built for maximum longevity, unlike standard "wash and paint" methods.