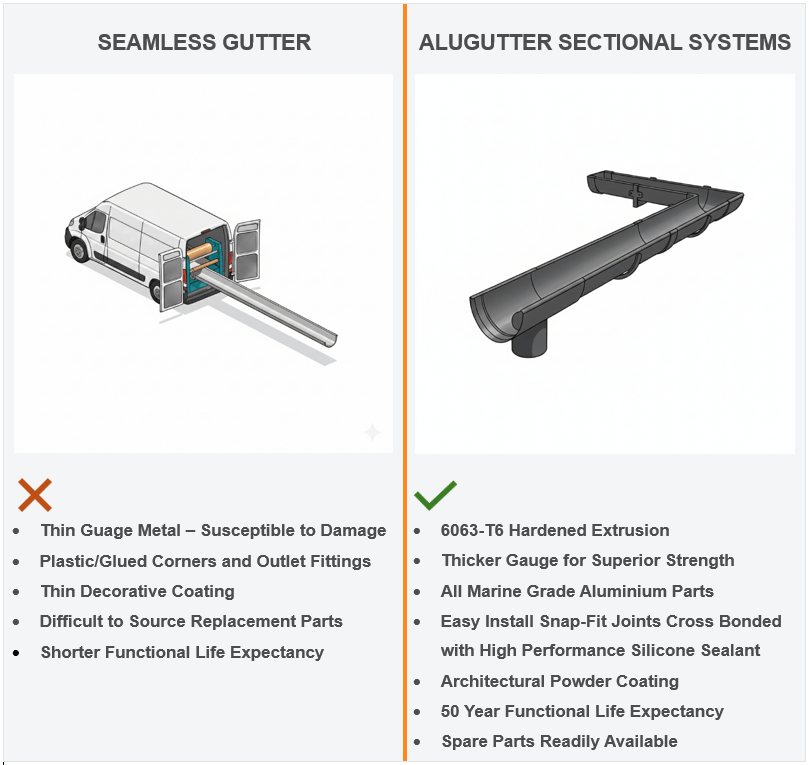

When choosing a rainwater system for your property, the term "seamless" is often marketed as the ultimate solution for leak prevention. However, for many homeowners and specifiers, the reality of seamless aluminium gutters often falls short of expectations when compared to high-grade, factory-manufactured sectional systems.

At Alugutter, we manufacture our sectional systems in-house to exacting architectural standards. Below, we break down the critical differences between site-formed seamless gutters and our factory-engineered aluminium rainwater systems.

1. Material Strength: 6063 T6 Hardened Extrusion vs. Thin Coil

The most significant difference lies in the "gauge" or thickness of the metal.

-

Seamless Gutters: Usually roll-formed on-site from thin coils of aluminium. To be flexible enough to pass through a mobile rolling machine, the aluminium must be relatively thin and soft - typically 0.7mm thickness.

-

Alugutter Sectional Systems: Our Half Round, Deepflow, and Box gutters are manufactured from 6063 T6 hardened aluminium extrusion and are 2 to 4mm thick dependant on profile selected.

By using a hardened architectural grade aluminium, our systems offer significantly higher impact resistance against ladders and snow loading—issues that frequently cause seamless gutters to deflect or "smile."

2. The "Seamless" Myth: Joints and Fittings

The name "seamless" suggests a system with no potential leak points. However, seamless gutters still require joints at every corner and every outlet.

-

The Seamless Issue: These corners are often joined using internal PVC components or low-grade sealants. Because aluminium and PVC have different thermal expansion rates, these joints are often the first point of failure.

-

The Alugutter Solution: Our fittings are manufactured from LM6 aluminium alloy castings or precision-welded extrusions. This ensures the entire aluminium guttering system expands and contracts at the same rate, maintaining the integrity of the seal for decades.

3. Superior Surface Finish: The Alugutter Process

Most seamless gutters are pre-coated in a factory before being rolled. This means the coating must be thin enough to bend without cracking.

At our UK factory, we take a more rigorous approach to our polyester powder coating:

-

Hand Preparation: Every length is hand-sanded to create a superior surface key.

-

Etch Priming: We apply a dedicated etch primer after degreasing.

-

Architectural Powder: We exclusively use Interpon D1036 external grade powders.

Many "on-site" systems skip these critical steps, leading to premature paint peel or "chalking" in UV light.

4. Maintenance and Longevity

If a seamless gutter is damaged—perhaps by a fallen branch or a wayward ladder—the entire continuous run often needs to be replaced. Because the machine that rolled it may no longer be available, or the contractor may have moved on, finding an exact match is notoriously difficult.

With an Alugutter system, individual lengths or aluminium downpipes can be easily replaced. As a national manufacturer, we maintain consistent profiles, ensuring that replacement parts are always available directly from the factory at industry-low prices.

Conclusion: Making the Right Choice

While seamless gutters offer a quick installation, they cannot match the structural integrity of a 6063 T6 hardened sectional system. If you are looking for a rainwater system that offers architectural strength and a premium finish that lasts 50+ years, sectional aluminium is the professional choice.

Technical Comparison: Alugutter Sectional vs. Standard Seamless

| Feature | Alugutter Sectional Systems | Standard Seamless (Site-Formed) |

| Material Grade | 6063 T6 Hardened Extrusion | Soft 3105 Grade Aluminium Coil |

| Aluminium Thickness | Up to 4mm (Architectural Strength) | Typically 0.7mm – 0.9mm (Lightweight) |

| Impact Resistance | High: Resists ladder damage and heavy snow loading. | Low: Prone to denting and "smiling" under weight. |

| Joint Technology | Cast LM6 Aluminium or Welded Fittings. | PVC Internal Connectors or Sealant-only. |

| Thermal Movement | Uniform expansion across all aluminium components. | Differential expansion between PVC and Aluminium. |

| Coating Process | Hand-sanded, Etch-primed & Powder Coated. | Pre-coated coil (thinner finish to allow rolling). |

| Paint Specification | Interpon D1036 (External Architectural Grade). | Standard UV-stable coating. |

| Maintenance | Individual sections easily replaced if damaged. | Damage often requires replacement of entire run. |

| Route to Market | Direct-from-Factory (Industry Low Prices). | Installed via local contractor (Retail Markup). |

For technical advice or to discuss your project requirements, please contact us and our team will be happy to assist.