Aluminium is the material of choice for modern rainwater systems due to its inherent strength and natural resistance to corrosion. Unlike steel or iron, aluminium protects itself by forming a natural oxide layer. Therefore, the application of polyester powder coating is primarily a decorative choice—allowing your gutters, fascias, and soffits to match a specific aesthetic or colour scheme.

However, simply because the metal won't rust doesn't mean the paint won't fail.

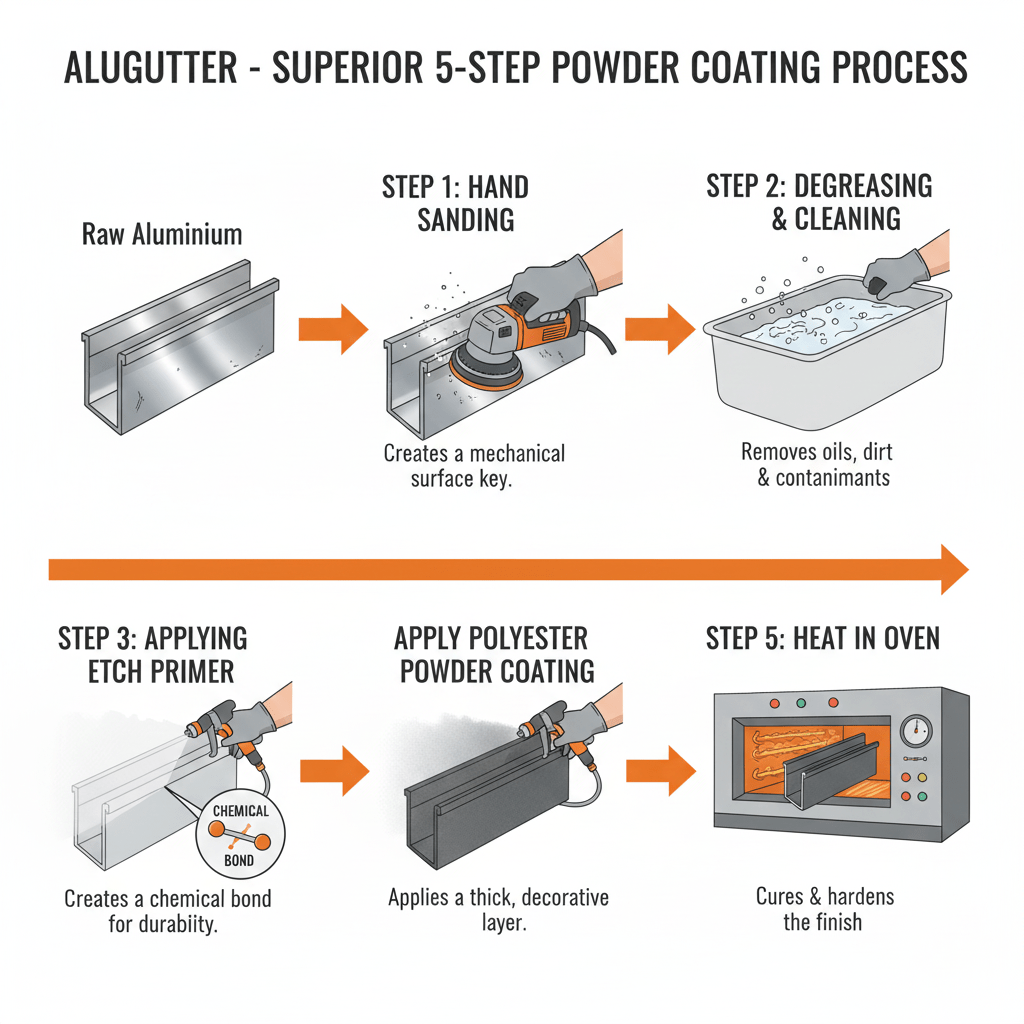

At Alugutter, we refuse to compromise on the quality of this decorative finish. While many in the industry opt for speed, we employ a rigorous, five-step process designed to maximise adhesion. This meticulous approach ensures that your Aluminium Gutters look as professional years down the line as they do on the day of installation.

The Problem with the Industry Standard "Wash and Paint"

To keep costs low and output high, many manufacturers use a streamlined coating process that involves little more than simple degreasing followed immediately by the application of powder paint.

While this is cheaper, it presents a significant risk for the homeowner:

-

Poor Adhesion: Aluminium’s natural smooth surface and oxide layer can make it difficult for paint to stick. Simple degreasing removes oils but fails to create a physical or chemical "key" for the paint to grip.

-

Aesthetic Failure: Without a proper foundation, the decorative coating is susceptible to peeling, flaking, or bubbling over time, leading to premature aesthetic failure.

Alugutter’s "No Compromise" Five-Step Workflow

We manufacture our systems in-house, from Aluminium Box Gutters to complex Wall Copings. This allows us to enforce a strict quality control regime that prioritises quality over speed.

Step 1: Hand Sanding (The Cost of Quality)

Before any chemical treatment, each component is hand sanded using an air-powered sander.

-

Why we do it: This is a labour-intensive and costly step that most volume manufacturers avoid. Hand sanding introduces controlled mechanical abrasion, creating a substantial physical "key." This physical roughening dramatically increases the surface area, giving the subsequent coating layers a much better surface to grip onto.

Step 2: Degreasing and Cleaning

The component is thoroughly degreased and cleaned to remove all manufacturing oils and contaminants.

-

The result: This ensures a pristine surface, as even minute traces of residue will compromise the effectiveness of the primer and the final coat, which is critical for the consistency of the finish.

Step 3: Applying Etch Primer

We apply a specialist etch primer to the prepared surface.

-

The Chemical Bond: The etch primer chemically reacts with the aluminium. This process is superior to a simple mechanical bond, as it creates a stable, chemically integrated foundation that dramatically improves the paint’s long-term staying power and resistance to separation.

Step 4: Apply Polyester Powder Coating

The component is then coated using only Interpon D1036 external grade architectural powders.

-

The Finish: The dry powder is electrostatically applied, ensuring full and even coverage over the primed surface. This top layer provides the aesthetic colour and UV stability required for premium architectural systems.

Step 5: Heat in Oven (Curing)

The coated component is moved into a high-temperature oven where the powder is cured.

-

The Fusion: Heat causes the polyester powder to melt and chemically react, fusing it permanently to the primed aluminium substrate. This crucial final step transforms the powder into the highly durable, solid decorative finish that is engineered to maximise the service life of our systems.

An Investment in Aesthetics

We understand that our customers choose aluminium for its long lifespan. While we cannot control the environment or maintenance of the system after it leaves our factory, our manufacturing process is engineered to give the coating the best possible chance of enduring alongside the metal itself.

By choosing Alugutter, you are choosing a product where the finish hasn't been rushed. We invest the extra time and labour into hand sanding and priming because we believe a premium material deserves a premium finish.

To learn more about our products, such as our range of Fascia and Soffits, or to request a quote, please contact us.