PRODUCTS

ALUMINIUM WALL COPINGS

9 products

Showing 1 - 9 of 9 products

| Estimated delivery: 5-10 working day lead time. |

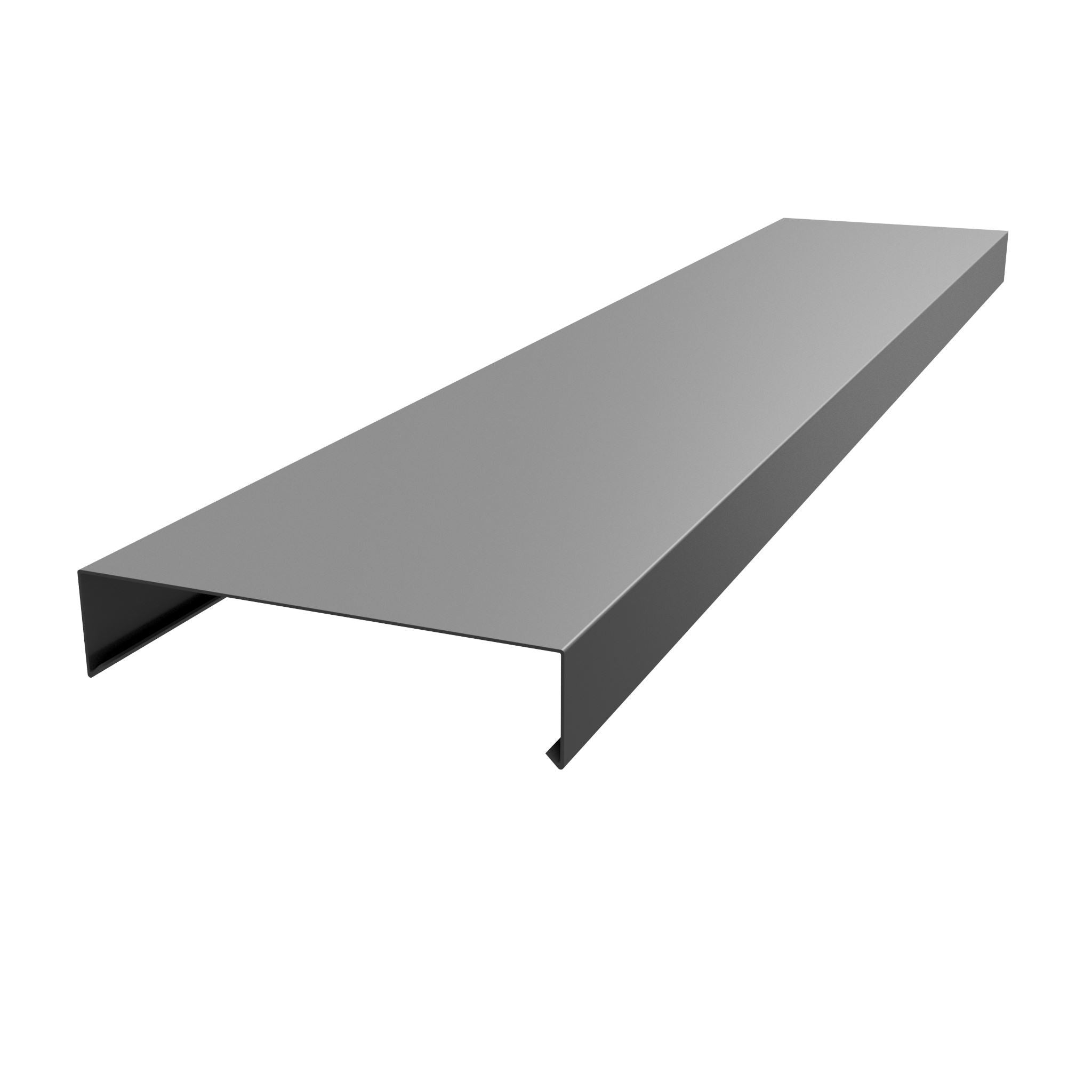

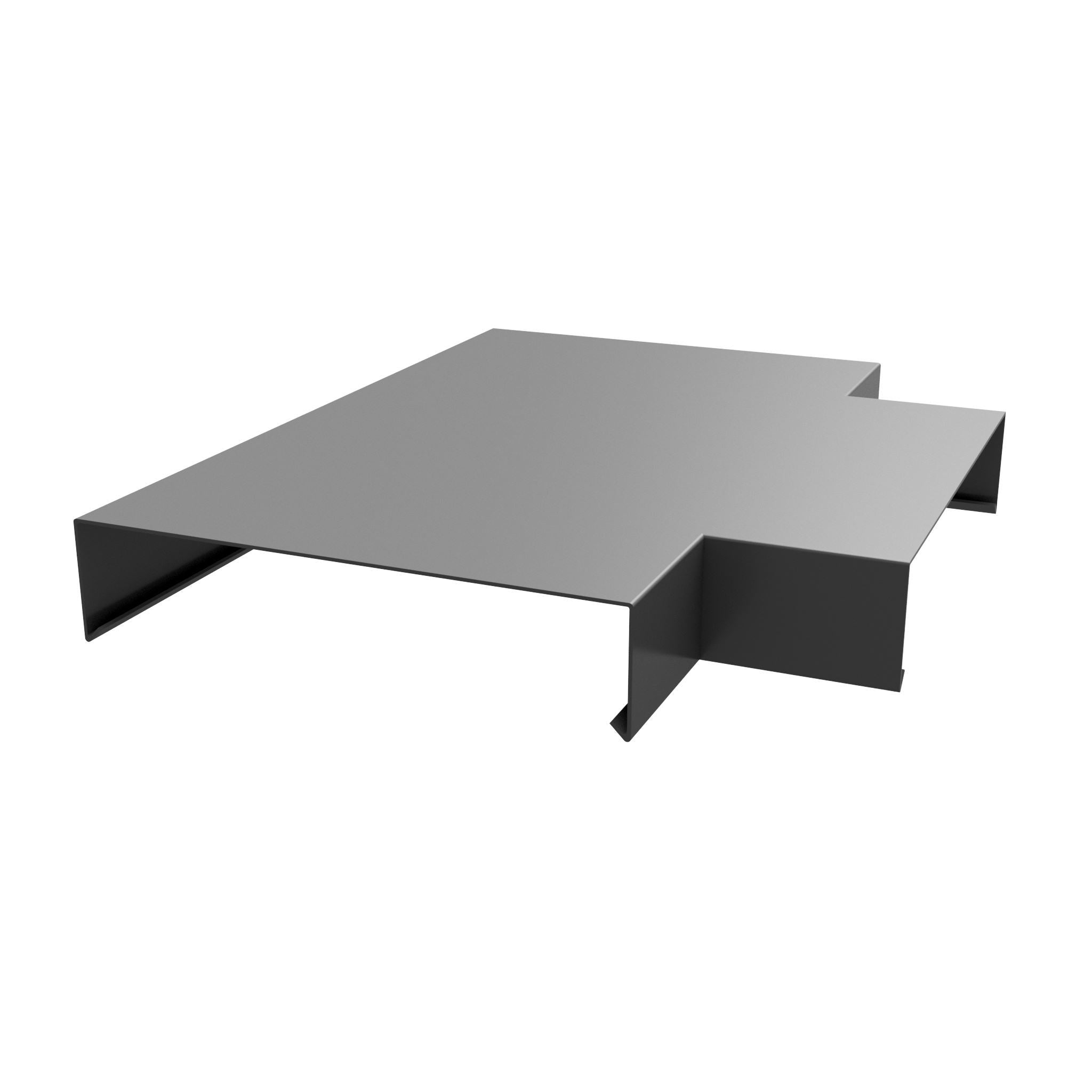

Aluminium Wall Copings - Secret Fix Parapet Coping Systems

Our aluminium wall copings provide a stylish, weathertight finish to flat roof parapet walls, terraces, and boundary structures. Manufactured in the UK from marine-grade aluminium and coated with external-grade architectural polyester powder paint, they ensure long-term durability and resistance to harsh UK weather conditions.

Our secret-fix marine-grade aluminium wall coping systems are ideal for domestic, commercial, and industrial applications. The coping lengths, angles, and stop ends simply click-fit into heavy-duty brackets, locking them securely in place for quick and easy installation. Fully sustainable and 100% recyclable, they comply with fire rating A2-s1,d0 under BS EN 13501-1, making them also suitable for high-rise buildings.

We offer a range of standard sizes and colours, but we're also experts in bespoke aluminium copings to meet your unique project needs—request a custom quote today.

Our Wall Coping Estimating Tool

Parapet capping is essential for weatherproofing flat roof extensions and commercial buildings. Our Aluminium Copings utilise a "secret fix" bracket mechanism to ensure clean lines and water-tight performance.

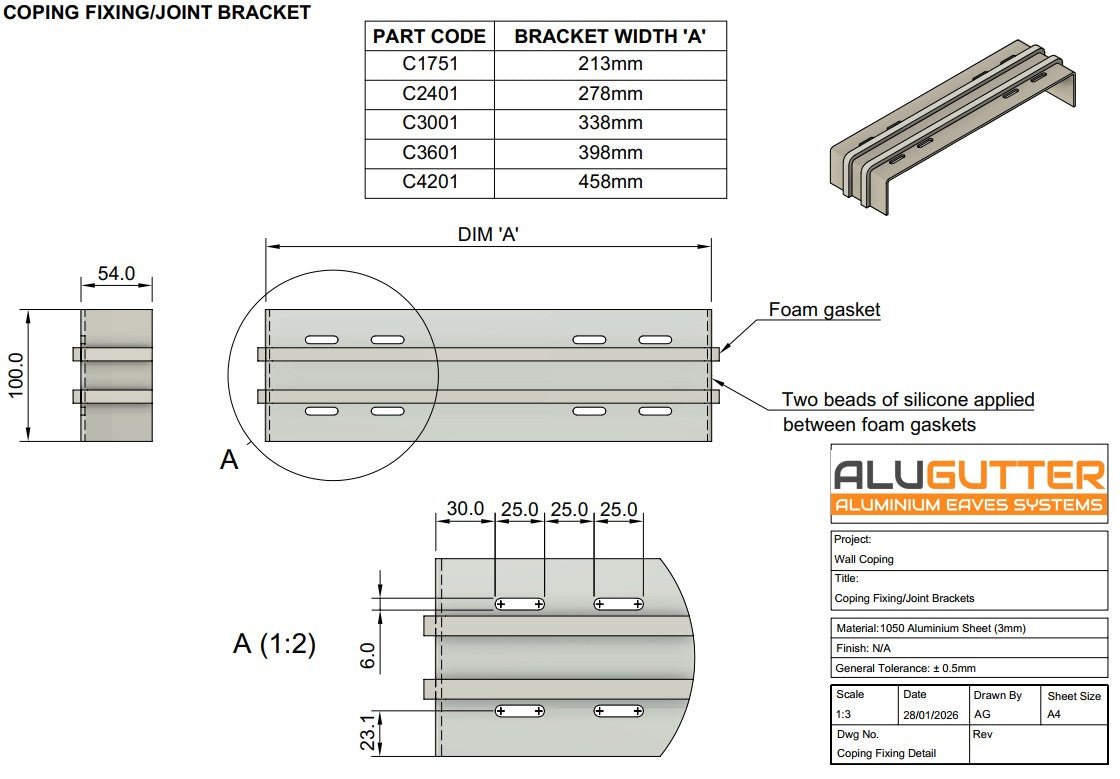

Calculating copings manually often leads to omitting the critical internal fixing brackets. Our tool eliminates this oversight by auto-calculating:

-

The exact number of 3m coping lengths.

-

The required quantity of hidden coping brackets/jointers (essential for wind resistance).

-

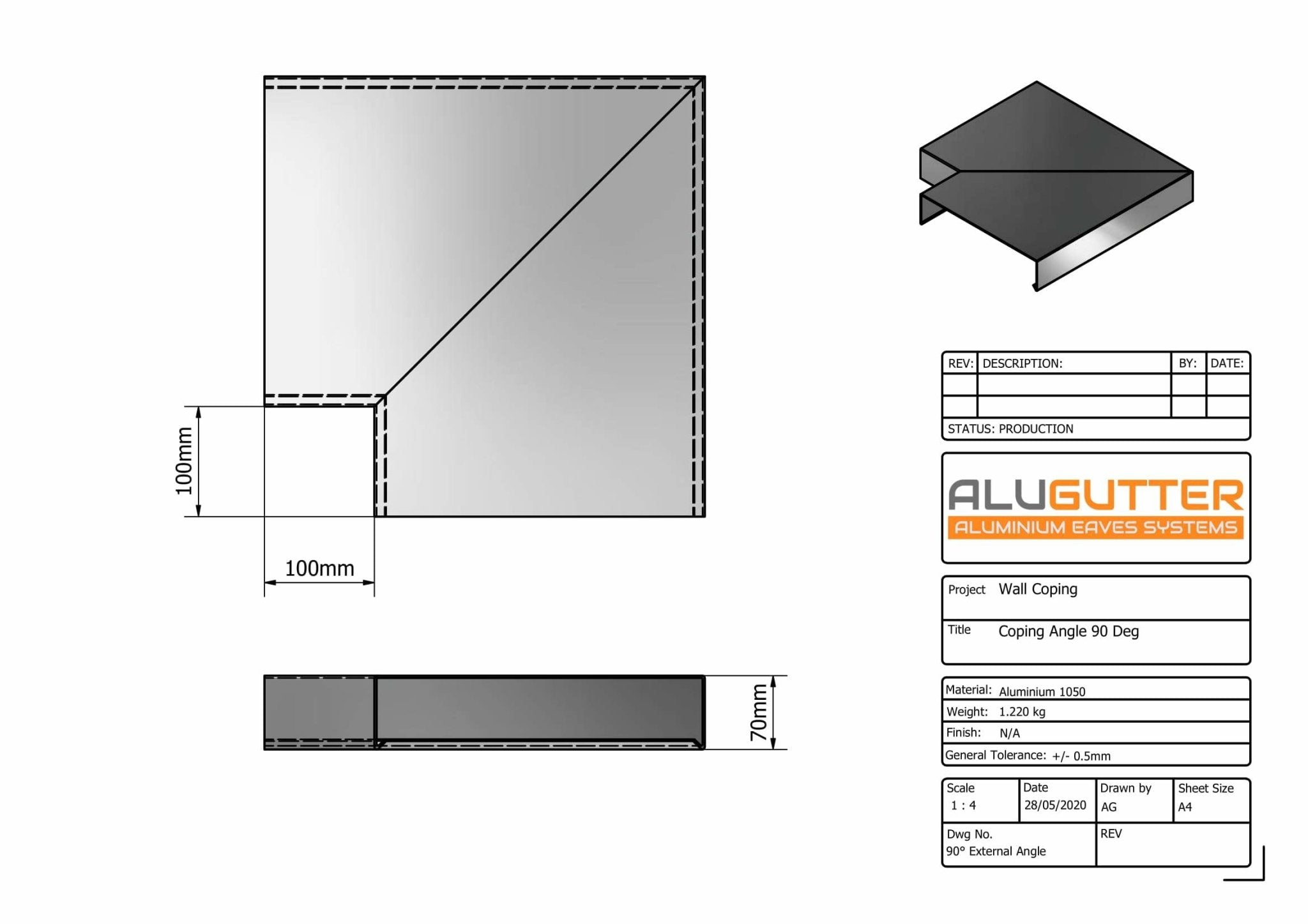

Necessary 90-degree corners.

> Try the Wall Coping Estimator Here

Key Benefits & Features of Aluminium Wall Copings

| Feature | Benefit |

| Manufactured from 2mm thick marine-grade aluminium | Provides exceptional strength and corrosion resistance for long-lasting performance. |

| Polyester powder coated in architectural external-grade paint | Low-maintenance finish that withstands UV fading and requires only occasional cleaning. |

| Fast and easy to install | Secret-fix system reduces labour time and costs on-site. |

| Fully sustainable and infinitely recyclable | Eco-friendly choice aligning with UK green building standards. |

| Suitable for domestic, commercial, and industrial use | Versatile for parapet walls, balconies, and high-rise buildings. |

| Fire class rating A2-s1,d0 | Compliant for unlimited use on any building height, including residential and commercial properties. |

| Designed and manufactured in the UK | Supports local economy with high-quality, reliable products. |

| Cost-effective system | Affordable alternative to stone with lower lifetime expenses. |

| Install level or with slight falls using packing shims | Flexible design for optimal water runoff without complex adjustments. |

| Bespoke coping options available | Custom sizes, profiles, and RAL colours to match your architectural vision. |

| Secret fix system | Clean watertight joints with no visible fixings. |

Technical Specifications and Performance

| Specification | Details |

|---|---|

| Material | 2mm thick marine-grade aluminium with PPC finish |

| Widths | Standard: 115-420mm; Bespoke available |

| Lengths | 3m standard |

| Profiles | Flat, sloped (3° pitch using spacers) or bespoke |

| Fire Rating | A2-s1,d0 (BS EN 13501-1) – Non-combustible |

| Bracket Spacing | Maximum 1.5m centres, with one at each joint |

| Colours | Standard range; any RAL/BS custom (extra charge) |

| Lead Time | 10 working days |

| Compliance | BS EN 13501-1; Fully recyclable and sustainable |

| Life Expectancy | 50+ years |

Benefits of Aluminium Wall Copings vs Stone Copings

When comparing aluminium wall copings to traditional stone options, the advantages are clear. Aluminium copings are lightweight (up to 70% lighter), strong, and available in a wide range of colours and finishes for greater design versatility. Unlike stone, which can crack, absorb moisture, or require frequent sealing, aluminium resists corrosion and weathering, making it a superior choice for UK climates. Plus, installation is quicker and easier, reducing project timelines and costs. For more insights, explore our blog on the top reasons to choose aluminium wall copings.

How to Install Our Wall Copings

Our wall copings are designed for straightforward installation, even on challenging sites.

Fixing Instructions

Aluminium wall copings are typically fixed to 18mm WBP plywood or fibre cement backing boards for a level surface. Space coping brackets at maximum 1.5m centres, with one at each joint. Apply two beads of silicone sealant (code SU1) to the brackets, then click the coping panels into place—hiding all fixings for a sleek, secret-fix finish.

The Manufacturing Difference: Durability by Design

Not all metal wall caps are equal. While competitors often skip steps, Alugutter employs a rigorous 5-stage finishing process to prevent paint failure:

- Hand Sanding: Every item is manually abraded to create a superior surface key.

- Chemical Degreasing: Removal of all contaminants.

- Etch Priming: A specialist primer is applied to chemically bond with the alloy.

- Powder Coating: Application of Interpon D1036 architectural-grade polyester powder.

- Curing: Baked for a hard, fade-resistant finish.

How to Cut Our Coping Profiles

Use an angle grinder with a 1mm metal cutting blade, dipped in tallow for lubrication to prevent burrs and ensure a clean cut. Alternatively, skill saws, jigsaws, or mitre saws with metal blades work well. Remove any burrs with a file, and apply touch-up paint (code SU6) to cut edges for protection and an aesthetically pleasing result.

Do Angles or Falls Need to Be Added?

Unlike lime stone copings that can stain facades due to calcium deposits, aluminium wall copings contain no microparticles that cause discolouration. They can be installed perfectly flat for a modern look. If a slight fall is preferred for enhanced drainage, simply place small packers under one end of the brackets during installation.

Fire Rating for Aluminium Wall Copings

All our polyester powder-coated aluminium wall copings are non-combustible with a fire class rating of A2-s1,d0. This makes them suitable for unlimited applications on residential, commercial, and high-rise properties, including balconies—ensuring full compliance with UK building regulations.

Maintenance Tips for Wall Copings

For visible areas like terraces, balconies, or garden walls, clean your aluminium wall copings easily with a mild soap and water solution. Wipe down with a damp cloth and dry using a microfibre cloth for a streak-free shine. This simple routine prolongs the powder-coated finish and keeps your copings looking new for decades.

Ready to protect your project with premium aluminium wall copings? Shop our collection now or use our free take-off calculator for accurate estimates. Contact us for bespoke options or installation advice.

Frequently Asked Questions About Aluminium Wall Copings

What are aluminium wall copings?

Aluminium wall copings are protective caps for parapet walls, terraces, and boundaries, providing weathertight seals and aesthetic finishes. Ours are made from 2mm marine-grade aluminium for durability.

What are the benefits of aluminium copings over stone?

Aluminium is lighter (up to 70% less weight), easier to install, corrosion-resistant, and recyclable, with no staining risks. It offers bespoke designs and lower long-term costs.

How long do aluminium wall copings last?

With proper installation, expect 50+ years. The PPC coating ensures resistance to UV, weather, and corrosion.

Are aluminium copings easy to install?

Yes—use secret-fix brackets spaced at 1.5m, with silicone sealant. No visible fixings; suitable for level or sloped setups with shims.

What colours are available for aluminium copings?

Standard range, plus any RAL or BS code. Lead time is 10 working days; contact us for custom pricing and samples.

What is the fire rating of these copings?

A2-s1,d0 under BS EN 13501-1, making them non-combustible and suitable for high-rise buildings.

Do aluminium copings comply with UK standards?

Yes, including BS EN 13501-1 for fire performance. They're also fully recyclable and sustainable.

How do I maintain aluminium wall copings?

Clean annually with mild soap and water. No frequent repainting needed due to the durable PPC finish.

Can I get bespoke aluminium copings?

Yes—custom sizes, profiles, and colours. Provide drawings for a quote.

Why choose aluminium for parapet copings?

It's lightweight, weatherproof, and versatile, offering better protection and aesthetics than traditional materials with minimal maintenance.