Description

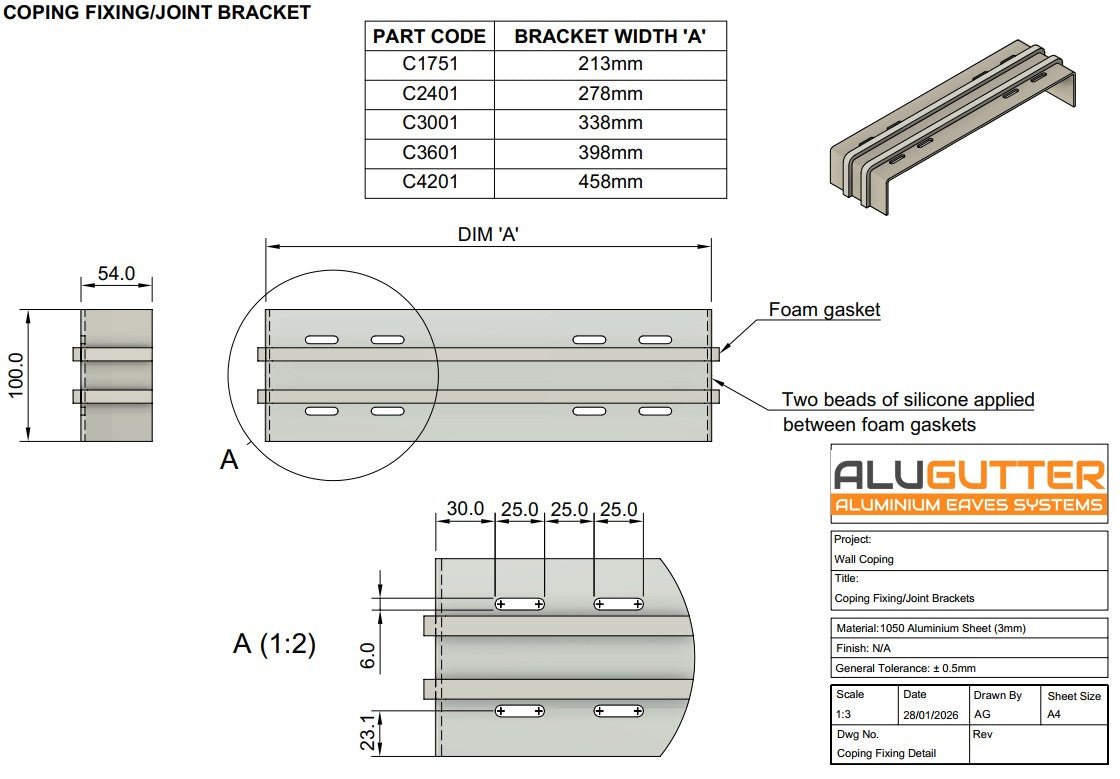

This aluminium coping fixing bracket is formed from 3mm thick 1050 grade aluminium sheet. It receives our 5-step powder coating process for lasting strength and rust resistance. This heavy-duty bracket secures coping lengths, angles, and ends in place. It supports quick assembly without visible fixings.

Typical bracket quantities required for installation: 2 per coping length, 1 per angle, 1 per T junction, 1 x stop end.

- Fix at max. 1500mm centres.

- Place one bracket under each abutting joint.

- Apply beads of silicone sealant to bracket surface, in order to create a weather tight seal, before placing coping sections.

-

Secure to backing boards using our fixing screws (part code SU11)

Please Note: Two 8mm beads of silicone sealant are applied parallel to the foam gaskets during installation. This seals the joint and bonds the items down into place. Our recommended sealant is crucial for long term durability of the system and we would not recommend that it is substituted.

If you are unsure of your requirements our expert technical team will be pleased to assist. Whether you have a list of parts, architectural drawings or hand sketches please email us your details.

We have a range of installation videos to assist contractors and show how our products are installed.

Our installation guides are available for download and give step by step pictorial instruction.

Our product data sheets contain all relevant information relating to our products. Each sheet also contains interactive tabs linking to other useful resources.

Used by building material specifiers, our product specification sheets give the relevant clauses and product details to be used in building design documents.

Architectural eaves gutter drawings that can be copied into architectural drawings ensuring correct construction design details are followed.

This page allows you to correctly size your gutter and downpipe system according to roof size - in full accordance with the BS EN12056-3 gravity rainwater drainage design standard.

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.